Building Workshops

Three best home workshop guides

Tools need a home. Setting Up Shop is the best guide I’ve found for designing a workshop. It focuses on the practical details that other workshop books tend to ignore, like how to arrange the lighting, or set up dust collectors, design the placement of wiring, even determining the height of work surfaces. It got me thinking about aspects of a shop I had not considered before and helped me improve the plans for my shop. Its very thorough coverage of sound, light, air, and movement options makes it the most useful of the three books mentioned here.

Workshop Idea Book is a scrapbook of hundreds of tips and clever solutions for a shop discovered by others. It showcases a lot of storage suggestions, and ideas for arranging stuff, such as how to handle large sheets of materials. Think of it as a kind of great, well-curated Pinterest board for workshops.

Both of these books are biased to wood. A better version of either book would include metal and plastic working tools, which are ignored. This failing is somewhat countered by The Workshop Book which tours through a much larger variety of work places. It documents several workshops installed in trucks, or fit into apartments, or made portable with everything mounted on casters. I found the greater diversity of shops covered in this collection to be more useful to me since my shop is more general purpose.

The great designer’s guide to creating a small-time prototype shop with laser cutters, 3D printers, solder stations, as well as drill presses and table saws, has not be written yet. In the meantime, these three idea books will get you started.

02/12/14Excerpt

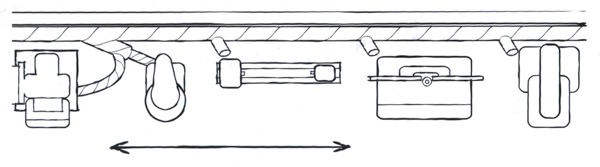

From Setting Up Shop

Three strategies for preventing long cords on portable power tools from ending up snarled and tangled are (left to right): Buy tools with detachable power cords, such as this Sawzall; fit each tool a short pigtail and plug it into an extension cord (using locking plugs) before using it; and refit existing power cords with tangle-resistant, self-retracting coil cords.

*

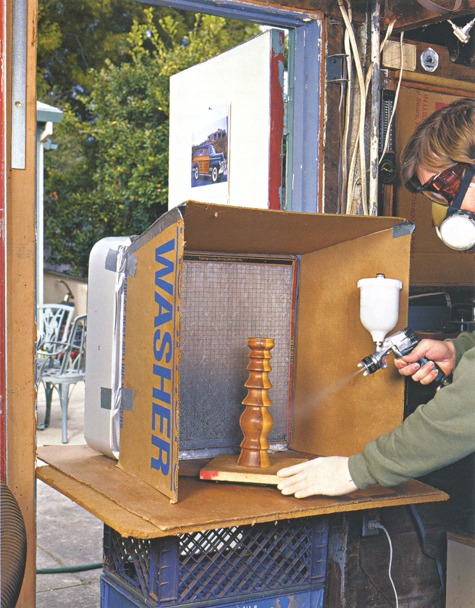

A box fan, a furnace filter, three pieces of cardboard, and a little duct tape are all it takes to build a simple spray booth that sets up in minutes in front of a window or doorway, allowing you to spray-paint or clear-finish parts and small projects.

*

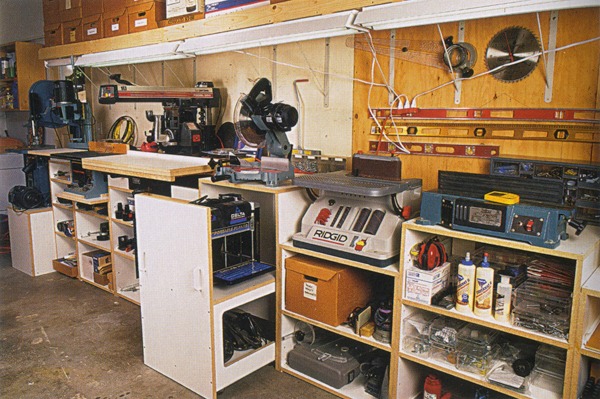

Orienting Machines in a Line

By carefully coordinating the positions and table heights of stationary machines, you can reduce the amount of clearance between certain machines. For example, by placing machines such as a shaper/router table, oscillating-spindle sander or disc sander, and horizontal boring machine in line, then setting them up with all their tables level and at the same height, a long workpiece may rest or slide on an adjacent machine's table (as shown here). Such an arrangement allows you to handle large or long work without having to rely on outfeed tables or roller stands for support. For this same reason, it's a good idea to level the tabletops of benchtop tools that are in close proximity to one another.

By setting tables to the same height and leveling them, a workpiece can pass over any or all of these machines.

*

Machine Layout against a Wall

Machines such as a bandsaw, drill press, router table, shaper, stationary sanders, lathe, joinery machines, and overarm routers are ideal to locate along a wall. Power and dust collection are easy to hook up.

***

From Workshop Idea Book

THREE SAWS IN ONE. For serious production work, two or more saws combined into one sawing station let you mill wood and cut joints without breaking down your setups. The three cabinet saws at Placeways Woodworking share a central shopbuilt table, which doubles as an auxiliary work surface.

*

PLUGGED PIPES. Make good use of inexpensive PVC pipe to store lathe tools and make them portable as well. Doug Stowe's pipes are mounted to a French-cleat system on the wall and can be moved to the lathe when needed. The top of the pipes are cut at an angle to facilitate loading, and the bottoms are plugged with wood.

*

SHOPPING IN THE SHOP. A converted shopping cart makes a convenient rolling hardware station. For his cart, dubbed the "piercing pagoda," Gabe Aucott added a plywood top fitted with divided boxes to keep screws and other hardware neatly sorted and a staging platform at one end. Below, a large plywood box holds glue and other assembly tools.

***

From The Workshop Book

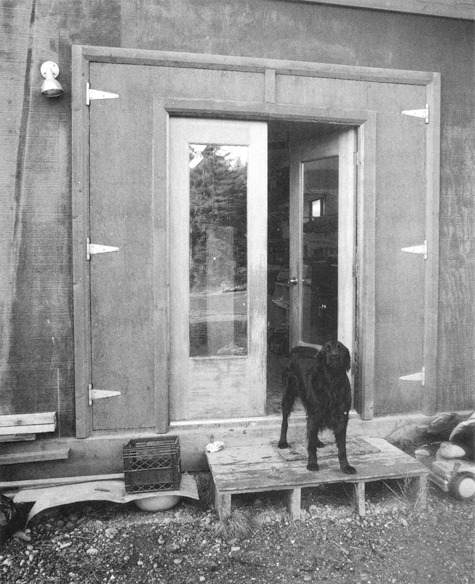

By hanging two narrow doors within two larger doors, Martha Collins can create four different openings to accommodate movement of objects large or small.

*

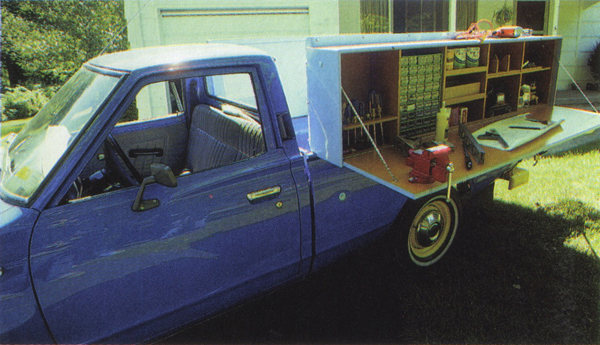

Two plywood cabinets flank the box of Lester Walker's Datsun Pickup truck. Walker, of Woodstock, New York, built one cabinet for woodworking tools and supplies and the other for camping equipment. On the road, the space between the two cabinets is covered with waterproof canvas and serves as a tent.

*

Donald Kinnaman packs the contents of an entire workshop into a 90-sq. ft. metal shed next to his Phoenix, Arizona, home. He rolls the machines he needs out onto the covered patio behind his house and goes to work.

*

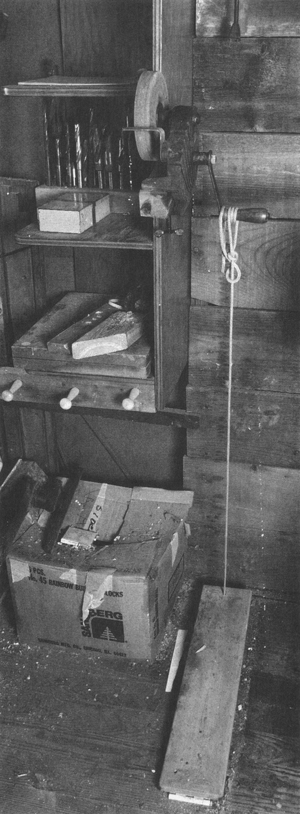

Years ago, when I worked in a shop without electricity, I had a hand-cranked grinder. It did the job, and I liked the slow speed, but I found it irritating to hold the tool with one hand and crank with the other. Fred Matlack converted his handcranked grinder to foot power by adding a rope and a hinged pedal. He gets the wheel going with the crank, then keeps it going with the pedal. The arrangement frees both hands to guide the tool.

Setting Up Shop By Sandor Nagyszalanczy 2006, 236 pages $17 Available from Amazon Workshop Idea Book By Andy Rae 2007, 170 pages $8 Available from Amazon The Workshop Book By Scott Landis 1998, 216 pages $17 Available from Amazon