Gar’s Tips & Tools – Issue #179

Weekly-ish access to tools, techniques, and shop tales from the worlds of DIY

Gar’s Tips, Tools, and Shop Tales is published by Cool Tools Lab. To receive the newsletter a week early, sign up here.

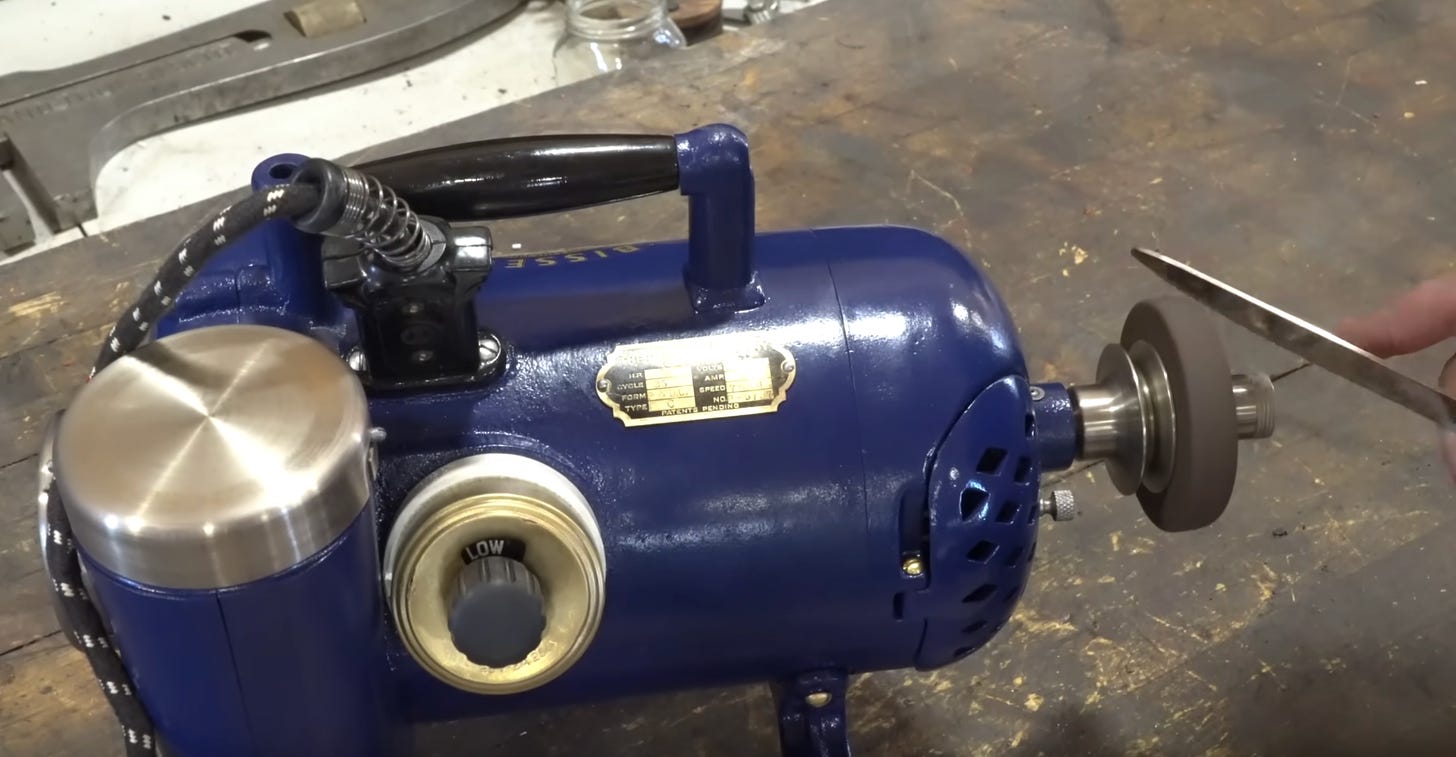

Restoring a 1914 Vacuum-Grinder-Buffer-Blower-Pulley(?)

I wrote about Hand Tool Rescue, one of my favorite maker channels, in the early days of this newsletter. If you weren’t around then and don’t know the channel, you should check it out. In it, Eric restores antique tools and machinery to near showroom quality. It’s mesmerizing watching him tear down rusty, crusty tools, often filled with cobwebs, insect parts, and rodent droppings. From there, he lovingly cleans, repairs, builds replacement parts, paints, and reassembles. It’s so gratifying to watch him put together the freshly painted parts and fire up the device for the first time in who knows how long. Each episode is also full of great tips on restoration and repair, like how to unfreeze old bolts, cleaning and sandblasting techniques, turning new knobs and handles on a lathe, lead testing, and more. In this episode, Eric restores a 1914 Bissell vacuum/grinder/buffer/blower/pulley. As he says, it’s the oddest combination of functions he’s ever seen. He also points out that, given the age of the tool, this was probably the first electric motor-powered device the owner ever had.

In Search of Lost Tools of Yesteryear

For decades, when I was a graphic designer (and after), I had a tool on my desk. It was a simple wooden dowel with a corked pin on one end and an angled burnishing tool on the other. It was stored in a plastic tube with a red plastic stopper. I used it for old-school paste-up (for wax-backed galleys on blue-lined layout grids). It was used for burnishing down the galleys and the pin was used for picking the galley up for repositioning. I loved this homely little gizmo and used it constantly. A decade or so ago, I lost track of it. I recently decided to try buying a replacement. Now, I want to use it for picking up tiny pieces of Plasticard and paper for positioning and placing in scale modeling. This has turned into a quest. First, I had to figure out what it was called. It’s a vinyl burnishing tool used in vinyl sign-making and applying automotive tint films. Amazon shows an exact copy of the one I had (see image above), but what you get is a slightly different tool with a thicker dowel, longer needle, and a vinyl cap over the needle (no plastic tube, no cork). I tried the manufacturer (which also showed the above image). Same tool as Amazon arrived. I know it’s silly — this modern version works exactly like the old one. I could also easily make my own with a piece of dowel, a pin, and a tiny cork. But I don’t want to do that. I want the exact tool of my youth. If you happen to know where I can get the tool as pictured above, please let me know.

A Guided Tour of Wire Strippers

In this very clear, well-produced video, Nils of LRN2DIY runs through all of the common (and not so common) features found on electronics wire strippers. The video is not only a great tour of this indispensable tool and its many built-in functions, but Nils offers a lot of great tips on using the features as he shows them.

Learning the “Zip Tie” Knot

On the highly-recommended knot tying channel, First Class Amateur, Brent shows how to tie two different knots (using paracord) that work like zip ties. The main knot he shows is a modified version of a Prusik hitch knot, common in climbing.

Tour Your Drawers

I’ve started doing a thing recently where, every few months, I will quickly tour the drawers and cabinets of my office-studio and garage shop to remind myself what I have and where it’s store (and what supplies and materials I may need to buy). What’s amazing is how frequently I still find something and think “Ah-ha, that’s where that is!”

Shop Talk

Readers offer their feedback, tips, tales, and tool recommendations.

Reader Rex Burkheimer responded to my thought piece on maker superpowers in the last issue:

Interesting post on your worldview as influenced by a maker’s mind. My story is similar I think. As a kid, I was disassembling broken mechanical items, repurposing the parts for something more interesting. Of course, there were model kits, microscopes, slot cars, bicycles.

As an adult, I worked in the automotive aftermarket parts world — sales, marketing, and IT. I also owned several retail stores concurrently with my day job with an auto parts wholesaler. The problem-solving I learned in my youth helped me in subtle ways such as evaluating new products – disk brakes! – as they came out. When you understand the design of a sub-assembly part, you get a sense of the design quality and likely point or frequency of failure. This guided my decision-making in choosing stock items as well as product lines. Success in my work let me obtain more and better tools.

Along the way, my hobbies including building PCs from salvage back when XTs and ATs were pricey. I haunted the Tandy surplus store. I was also heavily involved in sports car racing, as driver, crew, track worker, car owner. That led to an interest in machine tools, until I realized I was spending more time and money on machine tools than cars. I spent the last couple decades rebuilding old manual lathes (36 at last count), milling machines, drill presses, metal shapers, power hacksaws etc. while the race cars more often sat idle or were rented out.

Currently retired, with a nice workshop fully equipped with all the tools and materials I would have killed for as a kid. As that shop is an hour away, I have most of the same machines at my home as well – lathe , mill, drill presses, 3D printer, welder. Lately, I am into older garden tractors.

At the age of 72, I actively seek out projects, as well has help other folks new to the machining hobby. The latter works both ways, as a high school kid help me figure out a problem with my 3D printer. There is always a project waiting for my attention. Currently refreshing a South Bend metal shaper. Life is good!

I enjoy your blog.

Please Consider a Paid Subscription

Gar’s Tips & Tools is always free. But if you really like it and consider it truly useful to you, consider a paid subscription ($8/month). This keeps me in coffee and potato chips while I am working on this labor of love. If you really want to show your patronage, consider becoming a Hero of the Realm. I will send custom packages of goodies (books, tools, zines, and more) to all my Heroes.

Thanks to all those who have already subscribed. You are the Way Oil on my lathe.