A cool tool can be any book, gadget, software, video, map, hardware, material, or website that is tried and true. All reviews on this site are written by readers who have actually used the tool and others like it. Items can be either old or new as long as they are wonderful. We post things we like and ignore the rest. Suggestions for tools much better than what is recommended here are always wanted.

Tell us what you love.Categories

- Announcements

- Aural

- Autonomous Motion

- Backpacking

- Big Systems

- Clothing

- Communications

- Community

- Computers

- Consumptivity

- Craft

- Culture

- Dead Tools

- Deals

- Design

- Destinations

- Dwelling

- Edibles

- Every Day Carry

- Family

- Gardens

- Gareth's Tips

- General Purpose Tools

- Health

- Homestead

- Inner Space

- Just 1 Question

- Kitchen

- Learning

- Life on Earth

- Livelihood

- Living on the Road

- Maker Tools

- Maker Update

- Materials

- Media Tools

- Multiple Product Reviews

- No Stream

- Nomadico

- Paper World

- Photography

- Play

- Podcast

- Prove Us Wrong

- Readers' Gifts

- Recomendo

- Related Stuff

- Science Method

- Somatics

- Source Wanted

- Tips

- Tool Chest

- Tools for Possibilities

- Uncategorized

- Vehicles

- Videos

- Visual Media

- What's in My Bag

- Workplace

- Workshop

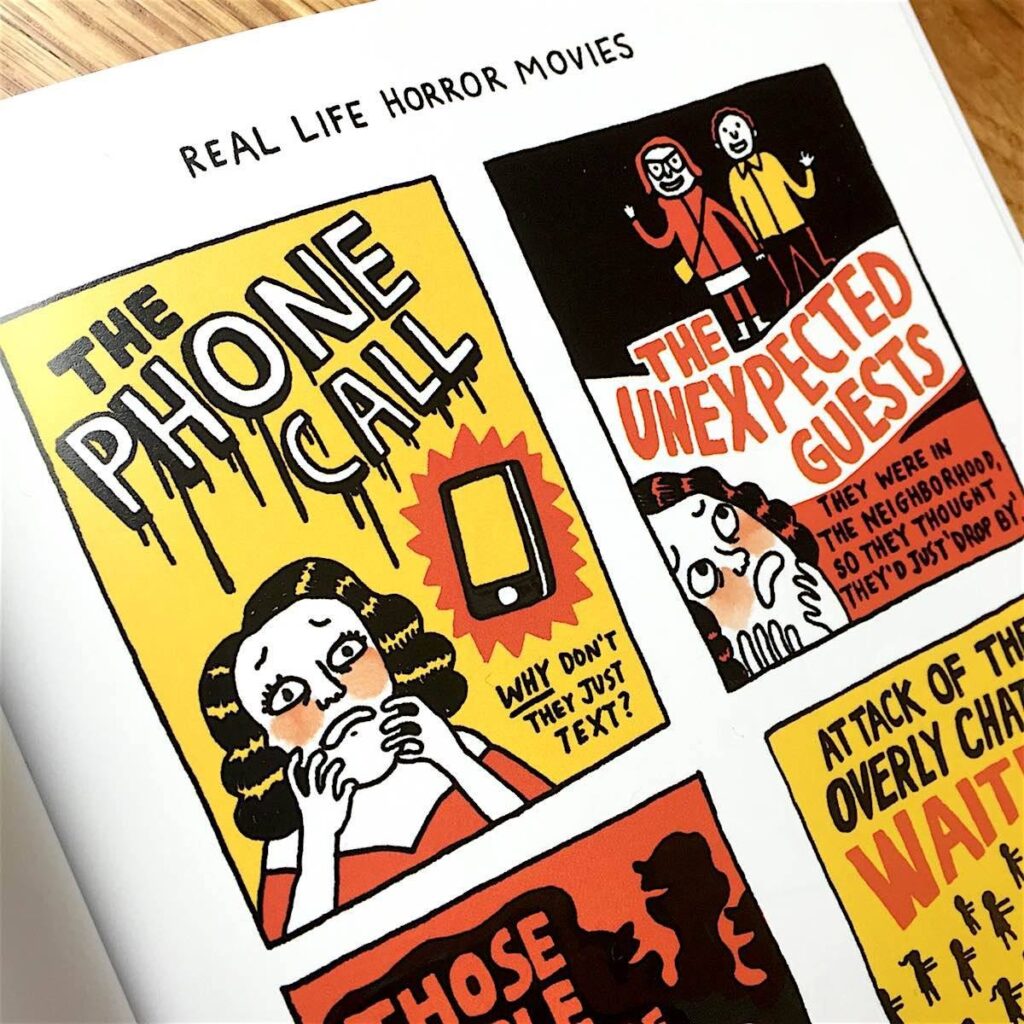

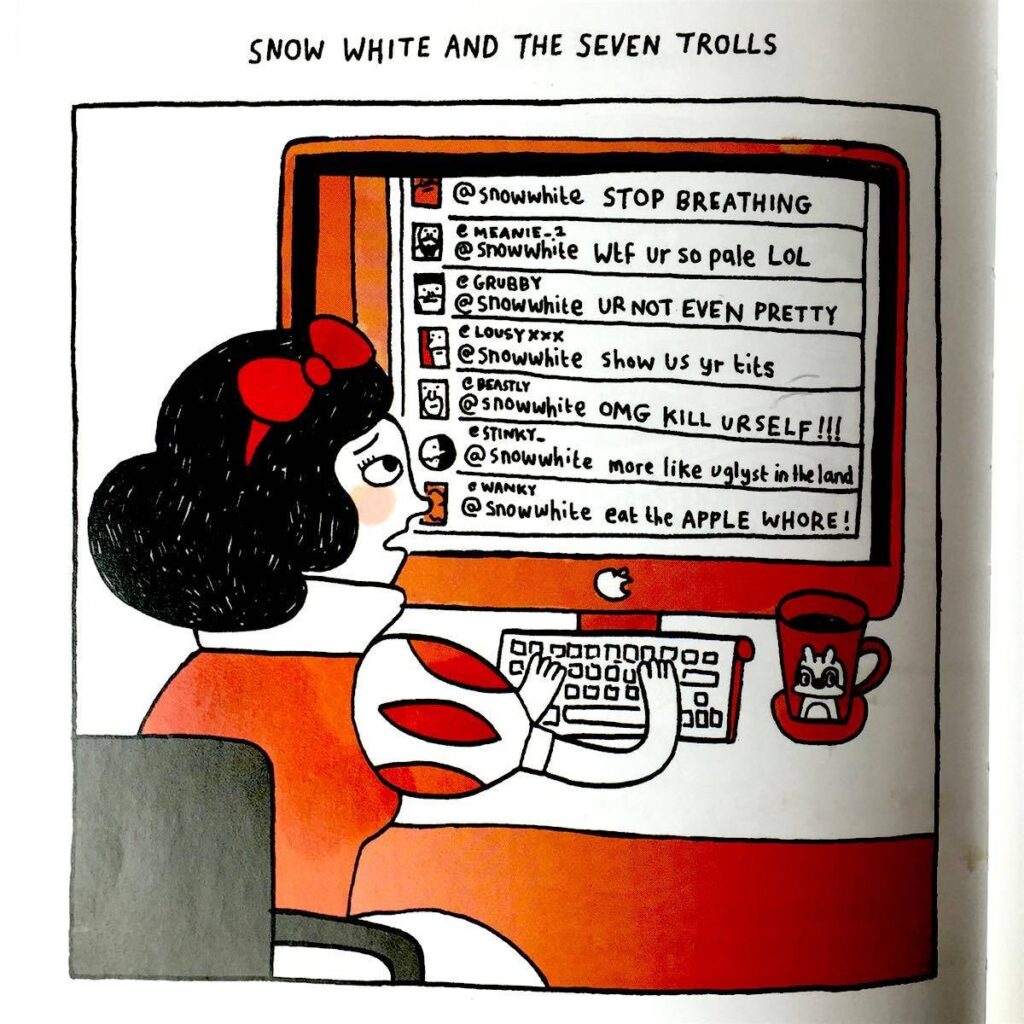

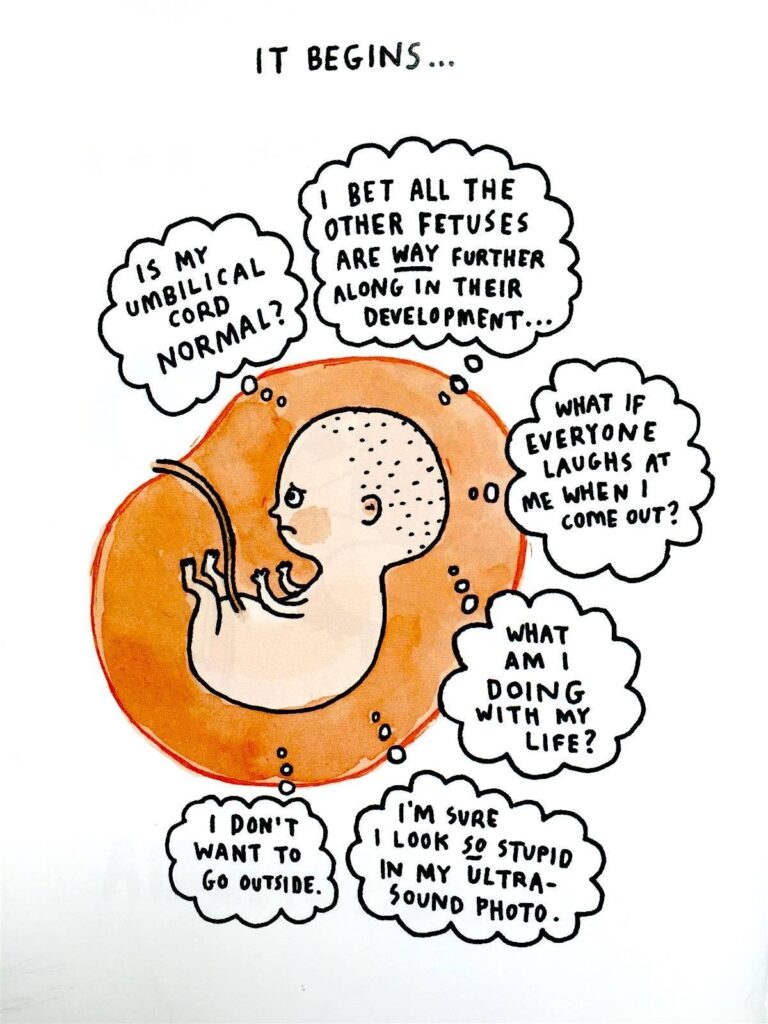

THE WORRIER’S GUIDE TO LIFE IS A HUMOROUS ANTIDOTE FOR ALL US PANICKERS OUT THERE

The Worrier’s Guide to Life

by Gemma Correll

Andrews McMeel Publishing

2015, 112 pages, 6.5 x 8 x 0.4 inches (softcover)

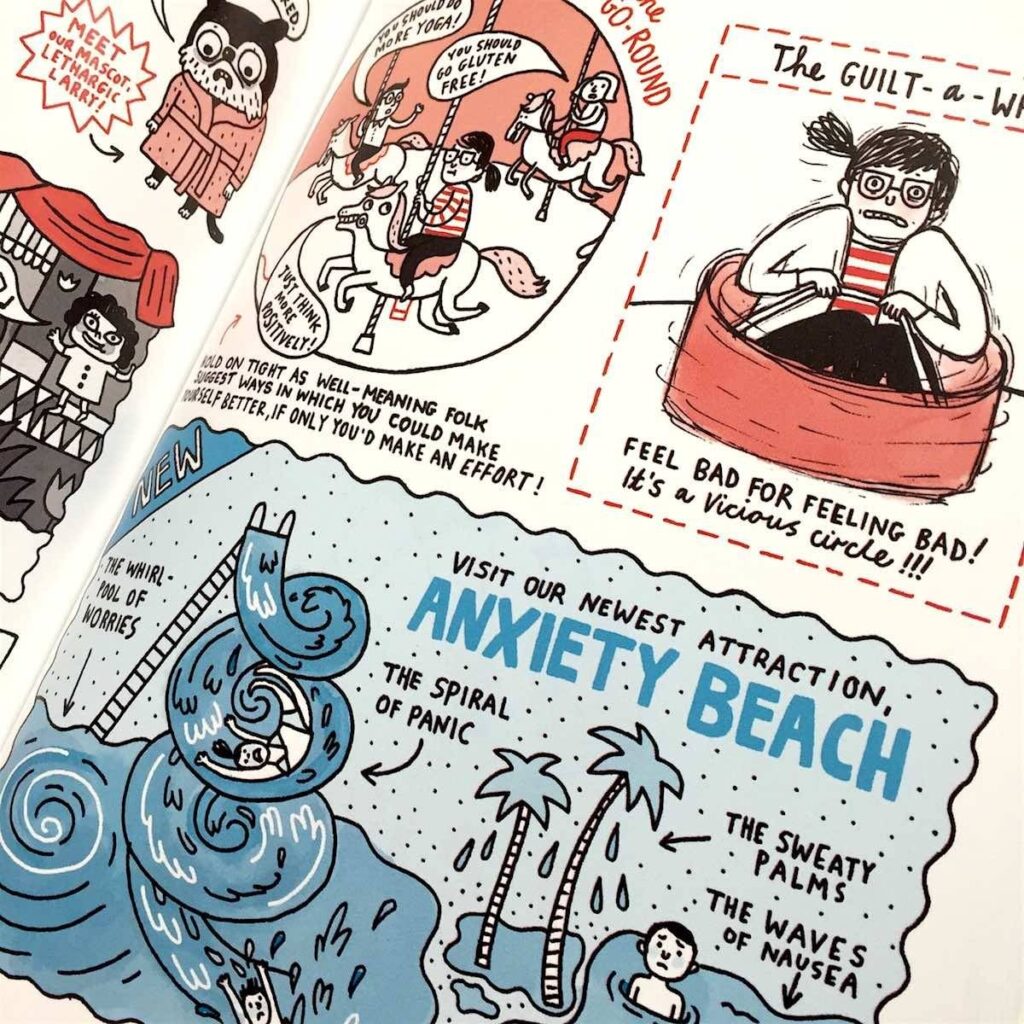

Are you an every-second second-guesser? Do pizza, sweatpants, and pugs sound like your perfect Friday night? Do you ever want to punch your brain in the face? Are you starting to feel anxious because I’m asking you so many questions? Find comfort in Gemma Correll’s new collection of comic snapshots, The Worrier’s Guide to Life.

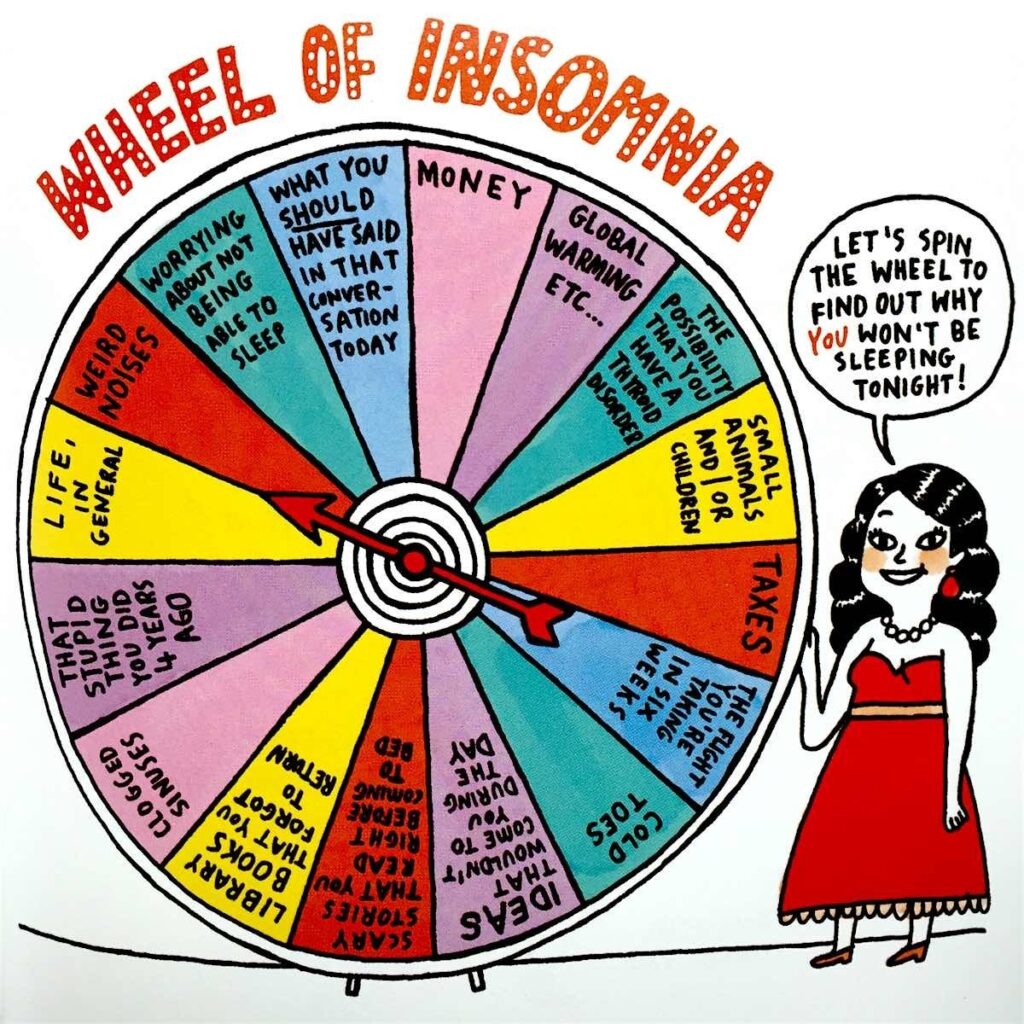

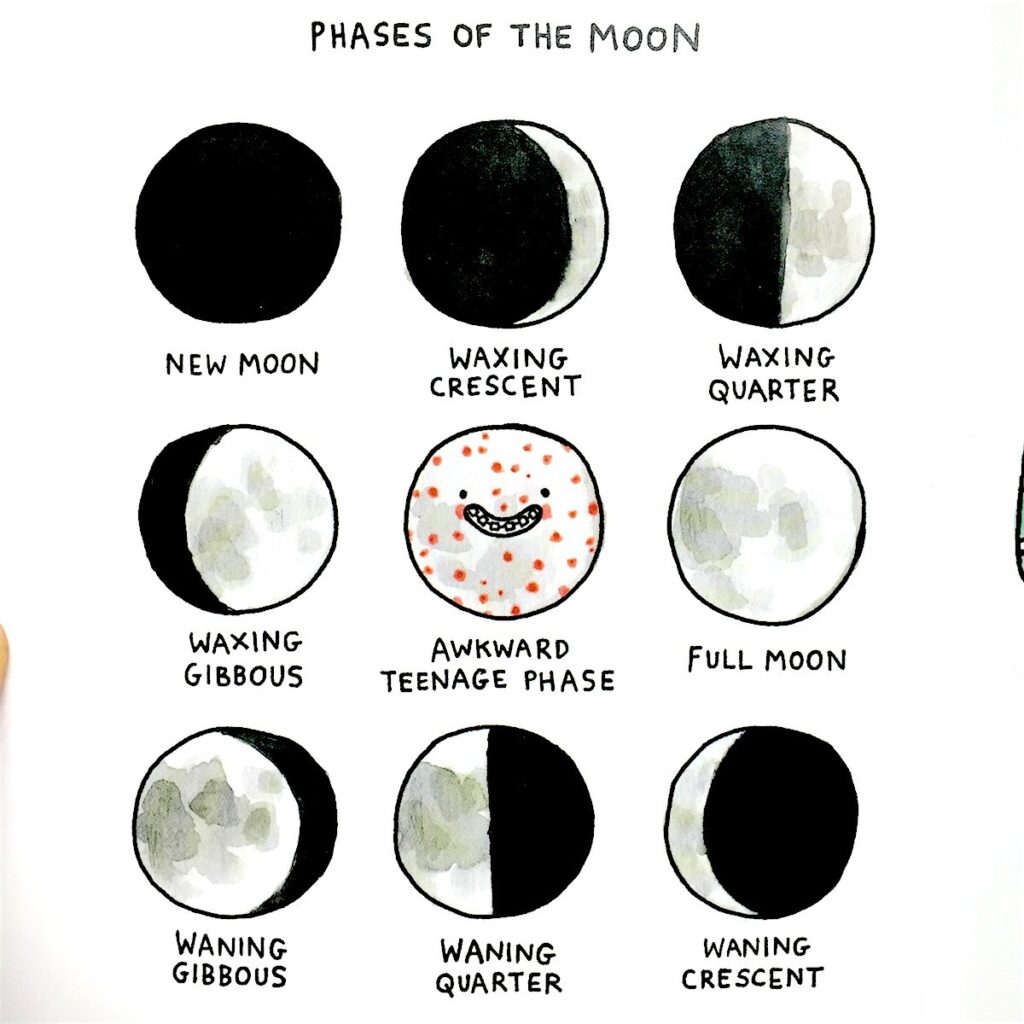

You can easily slip this slender book into your bag and bring it along to all those anxiety-producing other-people-filled situations that seem to dominate life. When faced with an overly crowded waiting room full of obviously contagious people whose germs will surely turn your sinus infection into a face plague, hide your nose in this book! If you’re forced to stomach a social gathering full of professional bloggers who couldn’t possibly look that good or be that happy in real life but ohmygod they do and they are and you haven’t showered in three days, steal away to a corner, flip open this book, and remember you’re not alone! Correll offers sketches of an anxious life, as lived by everyone from fetuses to fairytale princesses, interspersed with snippets from her ongoing series of punny visual lists. These delightfully silly sets include “Urban Birthstones,” featuring rings topped with a bit of styrofoam, a cigarette butt, or a balled-up passive-aggressive note, depending on your month, as well as “Pasta Shapes for the Depressed,” “Sexy Halloween Costumes for the Ladyeez,” and “Ye Olde Video Games.”

You can get a daily fix of Gemma Correll’s illustrated insights and anxieties via her various social media streams, but it’s lovely to actually flip through her work in a real-life book rather than, or in addition to, reading it on a scrolling screen. The Worrier’s Guide to Life also makes a fabulous gift for that perfect friend who never judges you for eating all the ice cream, texting her the conversations you have with your pet, or using Google like a magic eight ball. You know, the one who gets it. – Mk Smith Despres

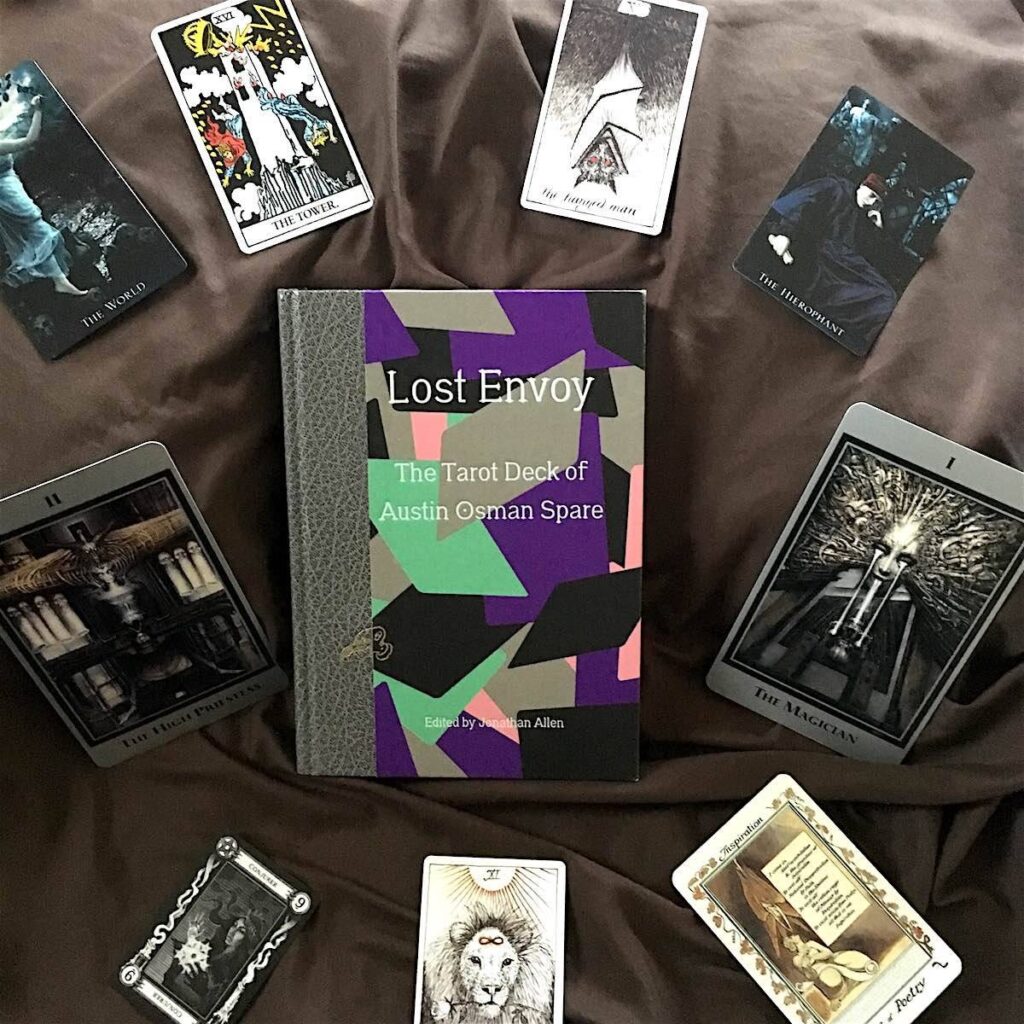

LOST ENVOY – ARTIST AUSTIN SPARE’S LONG-LOST TAROT DECK COMES TO LIGHT IN BEAUTIFUL BOOK EDITION

Lost Envoy: The Tarot Deck of Austin Osman Spare

by Jonathan Allen (editor)

Strange Attractor Press

2016, 336 pages, 6.5 x 9.5 x 1.25 inches

$39 (plus postage)

Buy a copy at Strange Attractor

The Victorian/Edwardian-era British artist and mystic Austin Osman Spare is still an obscurity to many. Like William Blake, with whom he shares numerous similarities (living largely impoverished, ignored by contemporaries, ridiculously prolific, mixing art and occultism), appreciation for Spare’s work and its significance have only increased over time. And where poet and occultist William Butler Yeats, during the occult revival at the turn of the 20th century, helped to finally bring Blake’s work to a wider audience (at least of intellectuals and bohemians), artists and occultists, such as Genesis P’Orridge, Kenneth Grant, and Alan Moore, at the turn of the 21st, did the same for Spare. Among other things, in Spare’s work, they found a very attractive system of artistic spellcasting which has come to be known as “sigil magic.”

But in all of the recent exhumation and examination of Spare’s art and occult practices, what people didn’t know is that Spare had created his own deck of tarot cards. Those cards were lost to time until they were discovered in the collection of the Magic Circle Museum, a UK stage magic society, in 2013. Since then, Spare enthusiasts have been dying to see the complete deck and to try and understand its significance to Spare and to the development of his oeuvre.

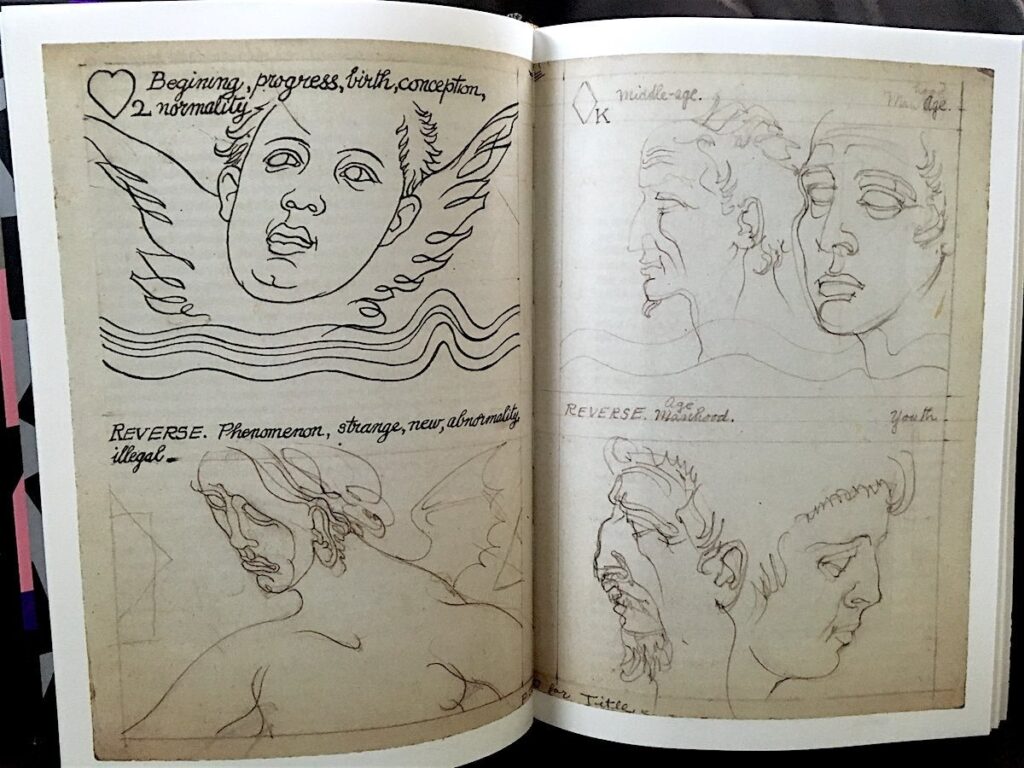

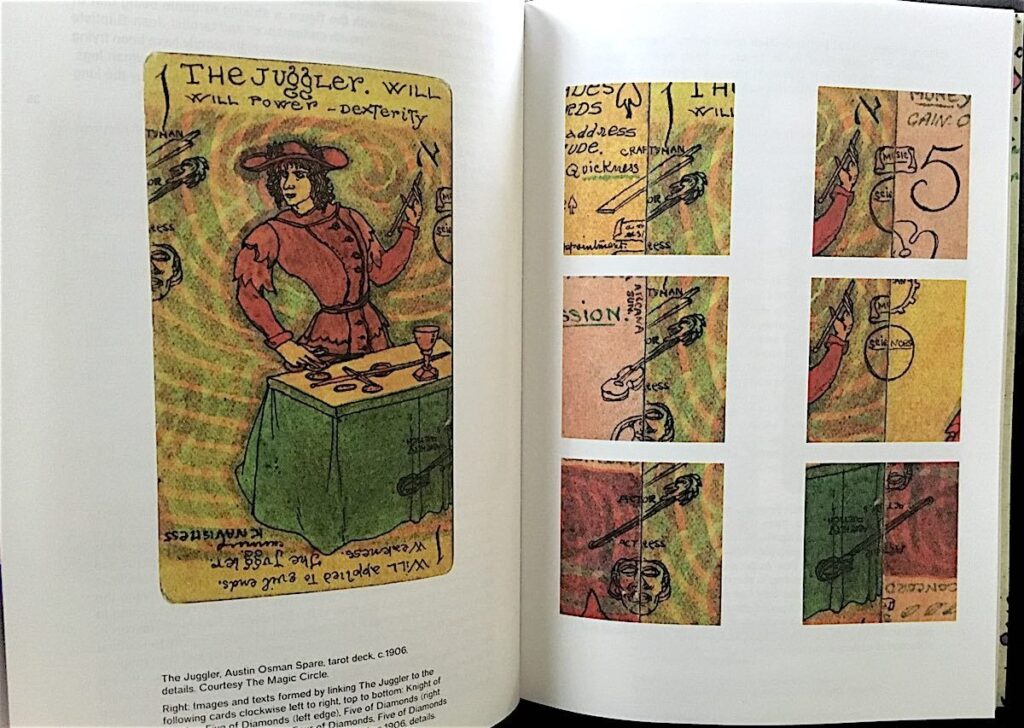

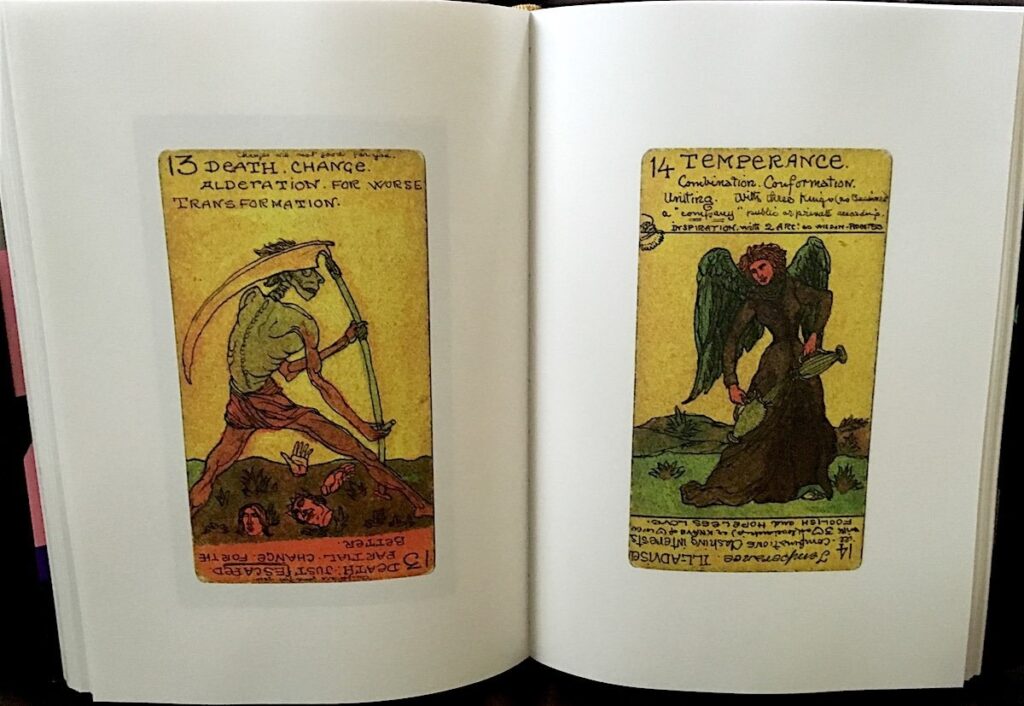

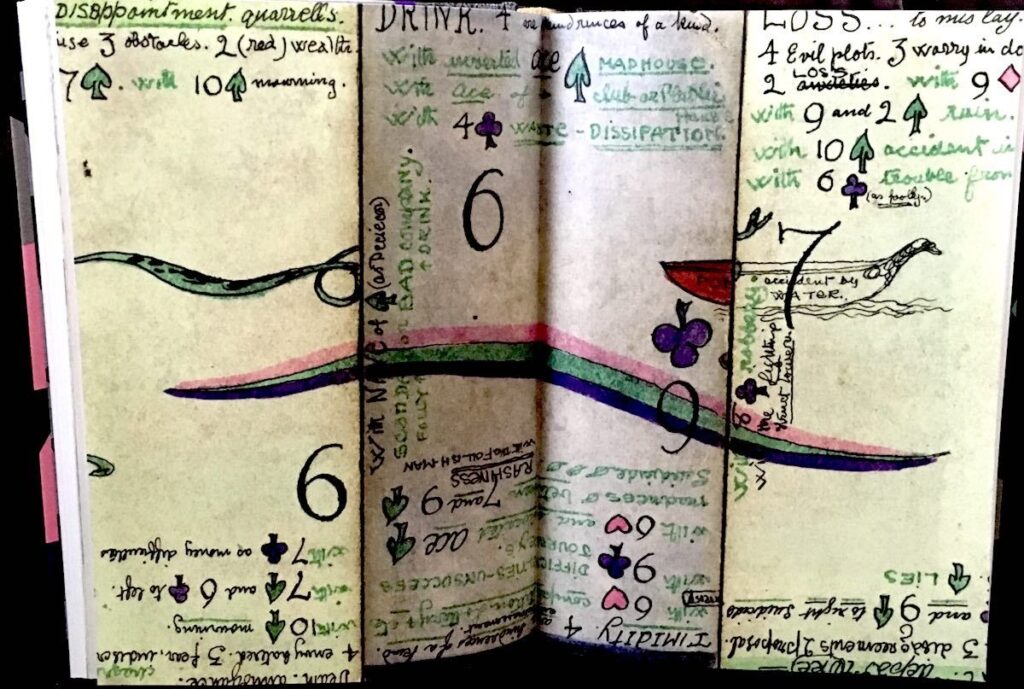

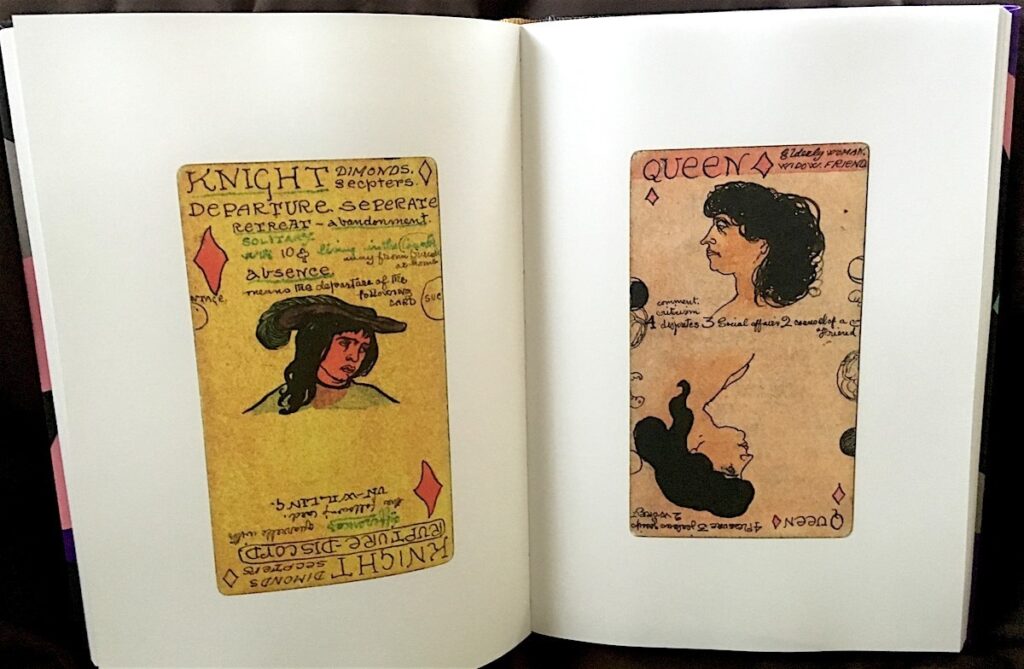

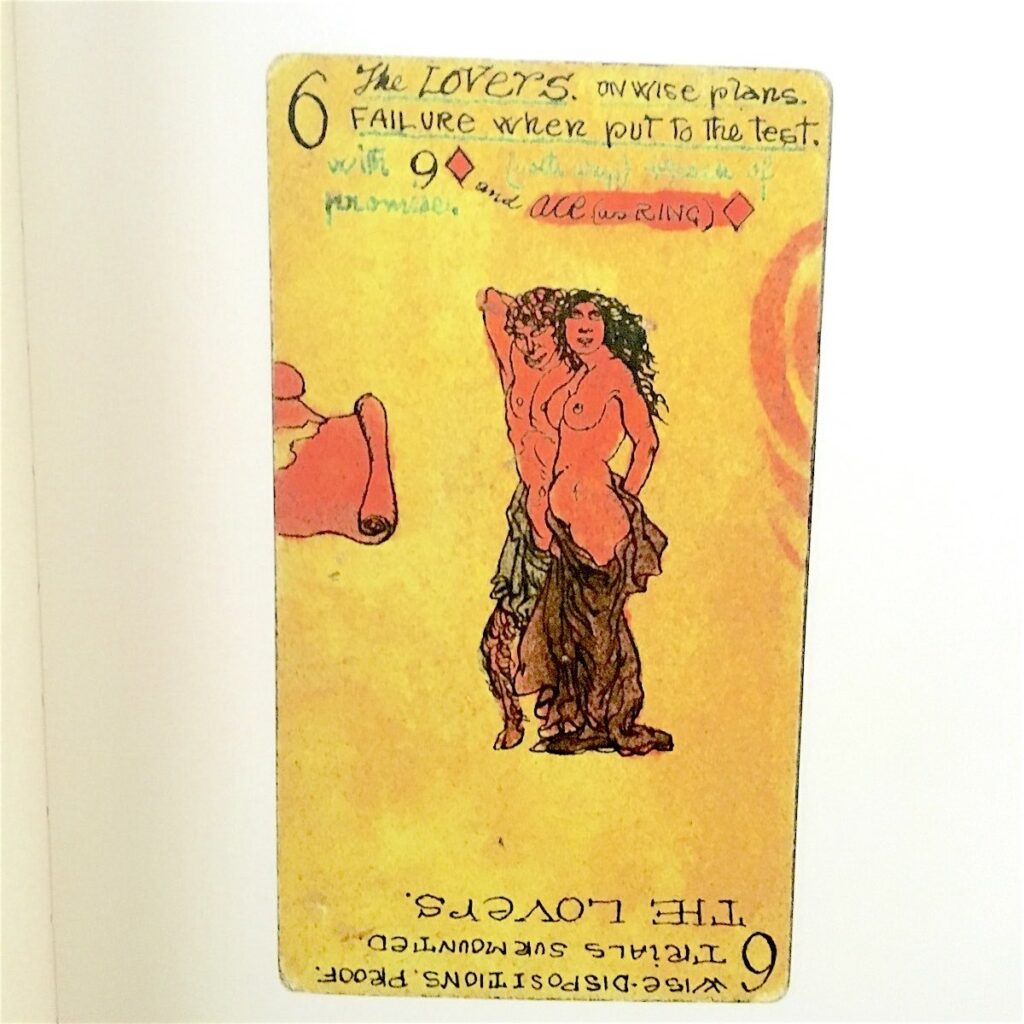

The always-impressive booksmiths at Strange Attractor Press have delivered on all of that in spades with their publication of Lost Envoy: The Tarot Deck of Austin Osman Spare. This absolutely gorgeous hardbound tome meticulously reproduces the cards, front and reverse, along with a concordance of all of the textual data found on the cards (which is quite heavy on some). The book also includes a very satisfying collection of essays by Magic Circle Museum curator and book editor Jonathan Allen, Spare biographer Phil Baker, artist and author Alan Moore, tarot academic Helen Farley, Spare historian and publisher Gavin Semple, and others. There is also an essay by Spare himself, “Mind to Mind and How by a Sorcerer.” Through these essays, we learn about fascinating differences in Spare’s deck, like his use of images and words that bridge individual cards (not found in other deck designs), how conventional playing cards and the culture of stage magic played a bigger role in his deck, and which historical tarot decks (and other occult currents) informed his stylistic and symbolic choices.

Lost Envoy is a must-have for anyone interested in Spare and will be right at home next to Phil Baker’s definitive Spare biography, Austin Osman Spare: The Life & Legend of London’s Lost Artist (also published by Strange Attractor), and the equally impressive Spare art books being lovingly published by the UK’s Fulgur, Ltd. My only burning question after finishing Lost Envoy is when do we get to play with an actual Austin Spare tarot deck? – Gareth Branwyn