A Little Nut Magic

Gareth's Tips, Tools, and Shop Tales - Issue #63

The latest issue of HackSpace magazine is now out. In it, I have a piece on molding and casting tips (page 86). Free PDF.

***

Like one of the tips in this issue? Share it on social media and link back here. It really helps in spreading the word. Thanks!

A Little Nut Magic

That’s nuts!

From Machinist’s Workshop: “When I find it difficult to place a ferrous fastener in an awkward position or in tight quarters, I slip a small, flat (¾” diameter x 1/8″) neodymium magnet into the index finger of a thin mechanic’s glove. When I put on the glove, I place the pad of my finger on the magnet. Now, the fastener will stick to the glove because of the magnet inside and I can position it where needed.“ [H/t Sean Ragan]

A Thread-Tapping Master Class

Making a tapping guide block.

In a recent Tested “One Day Build,” Adam Savage conducts a 40-minute master class on thread tapping, culminating in a project to build your own thread tapping guide from a chunk of acrylic. Lots of great stuff here, with tips and tool recommendations, such as Adam’s favorite tap set, tap wrench, and tapping fluid. [Via Maker Update]

Great Intro to Calipers

How deep is thy valley?

Hacker, engineer, Kyle Cothern has a most excellent introduction to analog and digital calipers. This essential precision measuring tool is intimidating to many makers. It shouldn’t be. This article should help demystify them, how they work, and why they’re so useful. It has some things in it I wasn’t even aware of, like various accessories you can get, such as a base attachment to hold calipers perpendicular to a flat surface when taking depth measurements. The one thing I don’t agree with is the recommendations on which calps to get. I don’t think you need to spend hundreds on a decent set of digital calipers (for most users). I’ll continue to swear by my under-$42 iGaging set. [Via Joshua Shachter’s Wheelhouse]

Maker Slang

Jargon, slang, and technical terms for DIYers.

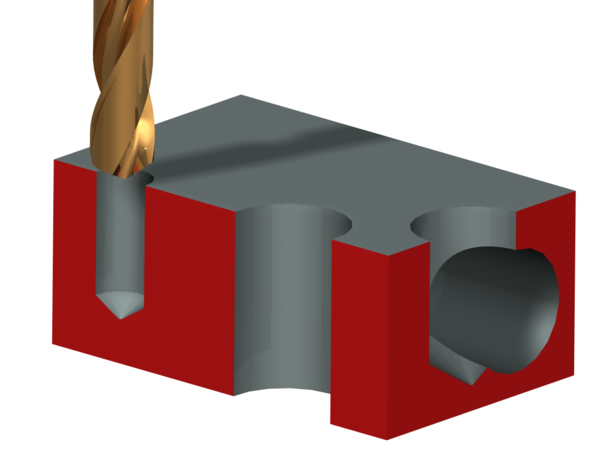

Blind hole (left), through hole (center), interrupted hole (right)

Blind hole – A hole that doesn’t penetrate the material all the way through. As opposed to a through hole which does go through.

Feel – The secret sauce of working the physical sciences. This is knowing things like how much force, pressure, tension, torque, etc. you can safely apply to a given object. This is largely a learned skill.

WDITOT -“Why Didn’t I Think Of That.” Not to be confused with ID10T, which is another thing entirely. [via Steve Roberts]

Welding boogers – Bad, ugly welds or a weld blob that has adhered someplace where you don’t want it.

An impressive booger weld.

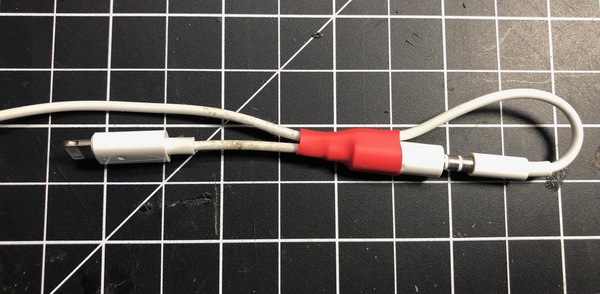

Heat-Shrink Earbud Plug Adapter

It’s not much of a lightning adapter when it takes 10 minutes to find it.

I got tired of hunting for/misplacing the Lightning-to-Mini Jack adapter for my Apple earbuds. So, I used some heat-shrink tubing to attach the adapter to the mini-jack cable.

Fixing LCD Screens

Reader John Ü shared this with me: “You can rescue even a badly scratched LCD screen on a resin 3D printer with a 3M headlight polishing kit. Found this out the hard way this week.”

10/1/20(Gareth’s Tips, Tools, and Shop Tales is published by Cool Tools Lab. To receive the newsletter a week early, sign up here. — editors)