Adding Foot Switches to Your Shop Tools

Gar's Tips & Tools - Issue #151

Gar’s Tips, Tools, and Shop Tales is published by Cool Tools Lab. To receive the newsletter a week early, sign up here.

– Send me a tip or tool recommendation.

–Tell me a shop tale.

-Buy my books (Tips and Tales from the Workshop Vol. 1, Vol. 2).

–Advertise your product, service, newsletter, app, book, tool, or anything you’d like to share with GT&T readers.

Adding Foot Switches to Your Shop Tools

Several years ago, I got a jeweler’s flex-shaft rotary tool. It came with a foot switch and I instantly fell in love with it. Once you power a shop tool with a foot switch, you won’t want to use anything else. In this video, Adam Savage installs a foot switch upgrade to his mini tabletop bandsaw. The switch is especially nice and addresses a problem I have with my rotary tool swutch. If I leave it plugged in, I can inadvertently step on the switch which sits off to the side of my main workbench. This switch has a toe-kick safety cover that prevents it from being engaged by accident. Adam doesn’t identify which foot switch he’s using, but it looks like a Linemaster. These are not cheap (at over $200 each), but he says you can often find them new or used on eBay for as much as half that price.

Building an Elevator for Your Shop

Like many makers, Wesley Treat has a loft in his shop. Such a space is great for storing materials, supplies, and equipment you rarely use, but getting stuff up and down from the space (usually via stairs or ladders) can be difficult, if not dangerous. Wesley solved this problem by building an electric-powered mini-elevator. I bet everybody with a shop loft is going to want one too after seeing this video.

Making a One-Handed Access Tool Wall

There are dozens of videos on building tool walls from lumber scraps, similar to this one. But Rex has some good ideas here that should be noted. For instance, all of his tool access is designed to be one-handed and most of the tools pull straight out rather than up and out. This way, you don’t take up valuable space on the wall.

Reading “Tools”

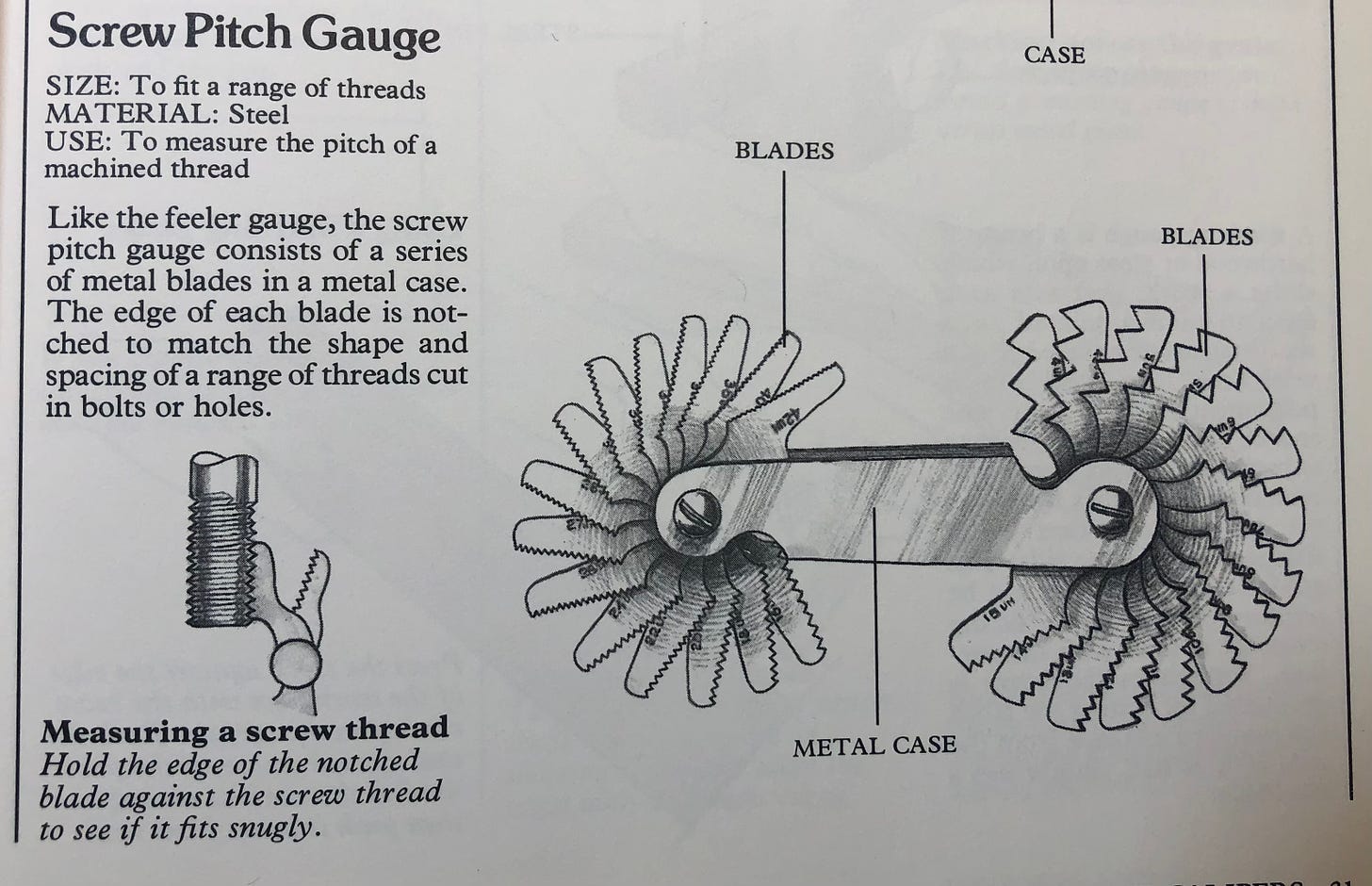

One of my all-time favorite DIY books is Tools and How to Use Them by Albert Jackson and David Day. I had a copy for years but donated it, along with a bunch of other maker/DIY books, to an artists maker/studio space when I moved to the west coast in 2021. After seeing it on a Digi-Key tweet a few weeks ago (where my tips book was also mention!), I realized how much I missed it. I ordered a used copy on Amazon for a whopping $2.98. I’ve decided to read it cover to cover to give myself a thorough education in common and not-so-common hand tools. Every few weeks, I will post an except here that I find particularly interesting, unusual, or informative. This week’s entry is the screw pitch gauge.

Things to Do with Sawdust

Woodworking creates sawdust. Lots of woodworking creates A LOT of sawdust. This waste material can be reused in a myriad of ways. Here are just some of them. If you have another use for sawdust, please share.

- Use it as a mulch in your garden: Sawdust can help retain moisture and prevent weed growth.

- Mix it with soil for composting: Sawdust can be used as a carbon source in composting, and it will break down slowly over time. Note: Sawdust can affect the pH levels of soil or compost. It’s important to monitor pH levels when using sawdust in these applications. When using it for composting, it should be mixed with other organic materials to ensure a proper balance of carbon and nitrogen.

- Create pathways in your garden: Sawdust can be used to create natural-looking pathway in your garden and help prevent muddy paths.

- Use it as a bedding material for animals: Sawdust can be used as a bedding for animals like chickens, rabbits, and goats.

- Use it as kindling for fires: Sawdust is highly flammable and can be used as kindling for fires.

- Mix it with wax to make fire starters: Sawdust can be mixed with wax to make fire starters that are easy to light.

- Use it to absorb spills: Sawdust can be used to absorb spills of oil, paint, or other liquids.

- Use it as a filler material in construction: Sawdust can be mixed with other materials like cement, clay, epoxy to create lightweight, durable building materials.

- Use it as a traction aid: Sawdust can be spread on slippery surfaces like icy sidewalks or driveways to provide traction.

- Mix it with birdseed: Sawdust can be mixed with birdseed to make it go further and provide a more natural habitat for birds.

- Use it as a cat litter alternative: Sawdust can be used as an alternative to commercial kitty litter, as it is highly absorbent and can be composted.

- As a mushroom substrate: Sawdust can be used for growing mushrooms.

- Make wood filler: Sawdust can be mixed with glue or epoxy to create a wood filler for filling in gaps or holes in wooden surfaces.

Caution: If the wood that the sawdust came from was treated with pesticides or chemicals, it could be harmful to use for things like animal bedding and garden mulch. It’s important to know the type of wood, how it’s been treated, and whether it is safe to use. Engineered woods like plywood, MDF, and particle board should be avoided for many of the above uses involving plants, animals, and composting.

Maker’s Muse: Grandpa Amu

If you haven’t seen Grampa Amu’s channel, subscribe now. I get inspired every time I see a new video. In this episode, Grampa Amu is given an old, cherished cooking pot that’s been used for so many years, a hole has been burned clean through the bottom. Using only the simplest of hand tools, he replaces the entire bottom of the pot with a metal pan. He manages to hammer the two items together with what at least looks like a leak-proof seal — no soldering! It would’ve been helpful to see the pot in-use, and full of liquid to show that it doesn’t leak.

Shop Talk

Last month, after I posted a video about Turning a Drill Press Into a Disc Sander, reader Chips ‘n Bits had a question.

“I have a question about the drill press as a disc sander. Would the friction and rotation of the disc put any lateral force on the quill? I ran into this issue (and gave a Makita drill driver about 1/8″ of runout) by mixing something too-viscous with a mixing paddle. Drill presses are made of sturdier stuff, but they’re not designed for lateral forces like routers/shapers. Hence: my question.”

Has anyone used a sanding disk on their press like this who wants to answer the question?

03/22/23