Jeri Ellsworth, CEO at Tilt Five

Cool Tools Show 148: Jeri Ellsworth

Our guest this week is Jeri Ellsworth. Jeri is an inventor, entrepreneur and amateur scientist. Her career started when she dropped out of high school and formed a business building, selling and racing quarter-mile dirt-track cars. In the mid-90’s she founded a small retail computer store chain, and in the 2000’s she launched her engineering career where she designed a wide variety of electronic components and consumer products. She’s passionate about educational outreach and maintains a YouTube channel devoted to demonstrating engineering and science techniques.

Subscribe to the Cool Tools Show on iTunes | RSS | Transcript | Download MP3 | See all the Cool Tools Show posts on a single page

Show notes:

Amray Electron Microscope

“I have an electron microscope. I got that because on my amateur science that I do. It’s one of those things people don’t think that an average human being can own in their garage, and it turns out it’s not that difficult to get them and it’s not that difficult to operate them. There’s all different types of electron microscopes. There’s types that are transmission, so they send electrons through the object that you’re trying to image. Mine happens to be a scanning electron microscope, so it beams a very small spot of electrons down on to the subject that you’re trying to image, and then it looks at what bounces off of it essentially. … To use the device, you have to sometimes pre-treat your subject, coat it with metal. Then, you put it inside. You pump a vacuum down, and then you start out with very low magnification. You zoom in a little bit, and then there’s astigmatism to this electron beam. So, it’s kind of off-shape. Then, there’s just knobs that you turn to make the beam round again. Then you zoom in a little bit, and then you make the beam round again. You zoom in, and zoom in, and zoom in, and just keep that astigmatism adjustment going until you’re imaging down into the low nanometers of feature size.”

Sputter coater

“A sputter coater is a really interesting device where you can put a sample or your subject into it. You draw down a vacuum and it has what’s called the target in it. The target the source metal that you want to coat something with. You pump it down. You inject in some heavy gas, usually something like argon which is neutral. Then, you pump a bunch of RF energy into it and there’s a magnet above this target which causes these ionized gas particles to strike the metal and it chips off the metal, and then it sputter coats the metal on to your object. So, you can sputter coat gold. You can do aluminum, copper, things like that. It’s pretty interesting. You can make mirrors with it.”

Plasma Etcher

“I’ve just been getting into doing plasma etching. It’s another exotic vacuum based tool. So a plasma etcher is pretty interesting. You have a chamber in which you put something that you want to etch and that you can etch all kind of things in this. I have a tabletop version. So, the working volume on that is about the size of a milk container, just give you like some real world volumes. … Basically the way it works is there’s a couple of components. There’s a chamber. There’s a manifold that lets you inject gases into the chamber under a greatly reduced atmosphere, and then there’s an RF generator. So, it generates a lot of RF. It’s pumped into basically an antenna that’s around the chamber. So, if you put for instance something that’s got a glassy coating on it like used in semi-conductors like there’s an insulating layer, silicon dioxide, you grow that on silicon which is glass. You put it into the chamber, and you mask off different areas that you want to etch through with photoresist for instance or other masking techniques, and then you inject a Freon or something that has fluorine atoms in it. Then you excite those fluorine atoms, then you have free roaming fluorine that etches the glass, turns to silicon fluoride, and then it just floats away and goes into your vacuum pump. Then, you can cut holes in these glassy layers. You can do some very interesting etching where you can etch to a particular depth. For instance, if you have a layer of glass on top of silicon, the fluorine atoms don’t really attack silicons. So, you can etch just right down to the silicon at the atomic level, and it will stop right there. You can etch very large areas like an entire wafer, like many centimeters across or down to almost as small as you want to go. It’s as small as you can pattern an image on to the surface and expose the glassy layer.”

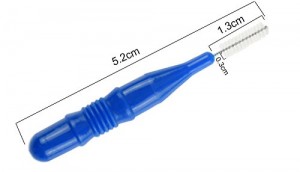

Interdental Brush for cleaning circuit boards

“I’ve discovered something just in the last month or two. There’s these little tiny tooth cleaners for cleaning between your teeth that have little brushes on them. They’re like little tiny brushes. There’s ones that it actually have a little … It looks like an old school pipe cleaner. So, it’s like a little wire with little bristles sticking out of it. They are fantastic. It’s my favorite new tool for putting circuit boards together. You just go to the drugstore and get them. I mean in the past, I would be trying to use toothbrush and other big brushes and you can’t get in between the little components and get all the gunk out. These are just perfect. Maybe it’s obvious to other people but it’s something completely new to me.

Also mentioned:

Tilt Five

“I’m super excited about it. I’ve been in the AR/VR space for a very long time. I got my start at Valve software which is a big video game company that got into doing hardware and the HTC Vive was one of their first VR products. There, I got introduced. I actually got to see about 20 years into the future just because we were prototyping, no limits on budget. We’d get the most expensive AR and VR gear. We could buy military grade and the most expensive tracking systems. I got to see what the future is like. … So, a group of us got together. People that worked in the company, we pooled our money and we actually purchased all the assets from the company, and we got all of this pre-production tooling, and all the technology and patents. We restarted a new company called Tilt Five and we’re doing something similar. It’s a little different, but based on a lot of the technology we developed there.”