Theodore Gray, Co-founder of Wolfram Research

Cool Tools Show 208: Theodore Gray

Our guest this week is Theodore Gray. Theodore is the cofounder of Wolfram Research, architect of the Mathematica Notebook System, founder of Touch Press, the BAFTA award-winning director of Disney Animated, which was the iPad app of the year in 2013, author of the million selling trilogy, The Elements, Molecules, and Reactions, and creator of a unique line of transparent mechanical models he calls Mechanical GIFs.

Show notes:

iPhone 11 camera features

It seems like in the history of cameras, it used to be that the camera body, was really almost irrelevant, because what mattered was the lens. And now it’s kind of gotten to the point where the sensors are so good, they’re so high resolution, they’re so sensitive, they’re so low noise, that it’s back to almost any camera body is fine, except for the most extreme demands of super low light or super high speed or something. But the other thing that’s happened is that old saying that the best camera is the one that you have with you … and the camera in the iPhone 11 Pro has sort of now crossed the threshold where I feel like I can comfortably go out into the field, or go on a trip and just not take a camera. It’s not just the lenses, they have this really clever software where you just pinch in and out, you can zoom in and out and it’s somehow magically blending the images from the three cameras, and it seems to do a really good job of it. But I think the big deal about this camera is that the wide angle is really wide angle, which is great. If you’re in a museum and you’ve got some gigantic steam engine in front of you, the cell phones that haven’t had super wide angle in the past were not adequate for that because you couldn’t capture the whole thing. I remember 10 years ago spending $1000 on a lens whose main calling card is that this is just massive pool of glass, three-inch diameter of clear aperture all the way through just to gather up light to be able to take a good picture in relatively low light. And now you have this phone with this lens you can barely see, this tiny little eighth-inch lens or something. It’s tiny. There’s just not much light hitting it. And yet somehow the sensors and the software have become so good that its low light performance is very respectable.

StitchMaster Quilting Machine

I should clarify, it’s actually not my machine. It is my ex-girlfriend/wife’s machine. Nina Paley is a fairly well-known and acclaimed animated filmmaker who bought this machine while we were married, and now we’re not married anymore, but the machine is still in my office because it’s too big to move. So it’s there and we exist with it together, and we make quilts with it. Some of them are art quilts that she makes and some of them are periodic table type quilts that I make. It’s Chinese made. There’s very few of them in the US, but there is a dealer in Missouri, Quilting Masters that we went through to buy it and they sell them here, but there’s not a whole lot of demand for textile production machinery in the US anymore. Basically what it does is imagine you have an X-Y pen plotter, like an old school pen plotter, except instead of a pen it has a sewing machine, and instead of being a foot square, its working area is eight feet square. The whole machine is more like 10 or 11 feet square. And what’s moving around is a high-speed industrial sewing machine on an X-Y track. And then what you do is you stretch fabric, typically like a sandwich of fabric with batting in between, and then you just give it a file. It’s a very simple set of lists of X-Y coordinates and you tell it, “Stitch along this path,” just like a pen plotter. It just runs along and it stitches.

LibreCAD

One of the things that I do is design acrylic models. They are these little kits you put together and it’s an engine or a steam engine or a lock, I have a really nice one for a combination lock, and they’re made out of laser cut acrylic. And so I have to design the patterns, the shapes to cut, and it’s by its very nature 2D because that’s what a laser cutter does. It cuts a two dimensional sheet. And it’s actually, sort of mathematically speaking and operationally, quite similar to stitching, because again you have an X-Y path that it’s following. But the kinds of designs that I’ve done are very different, so I needed to pick a CAD program and AutoCAD would be the obvious choice, but it’s ludicrously overpriced and as a person who has been involved with selling commercial software, I felt like I probably shouldn’t pirate it. So I found this thing called LibreCAD, which is a free open source CAD program that basically just does 2D. I think it has some kind of 3D features, but I never looked at that. And I find it endearingly simple. It has a lot of bugs and I can’t get the splines to work right so I don’t use splines, but I find that it’s exactly the right level of simplicity so that I’m not struggling with its features all the time. It just lets me draw clean, simple, 2D shapes really easily and then put them in the laser cutter and boom, they’re there. And you can literally have a 30 second or a one-minute cycle time. You do something in the program and there it is.

Anycubic Photon S

I love the idea of a 3D printer, but the actuality of filament 3D printers I’ve always found very disappointing, and I didn’t want to use and don’t use any parts in any of my kits that are printed that way. A laser printer is a fundamentally two-dimensional and if you want to have a third dimension to the parts, you can’t do it with a laser cutter. And the situation was brought to a head when I decided I really wanted to make an internal combustion engine and the crank shaft of an internal combustion engine is just a deeply three-dimensional object. There is just no way around it, you need the third dimension. And so I was trying to figure out how I can make that part so I can include it in the kit, and I’m not going to 3D print it, it would not be strong enough, it would be too rough, it just wouldn’t work. I was looking at Formlabs resin printers and these printers are $5000 or something, they’re very expensive resin printers, and the resin is ridiculously expensive. And so I had rejected that a few years ago but then I looked again earlier this year and I discovered that there are now literally $200 stereolithography printers. The one I bought, I think it was like $450 or something like that. I got the slightly higher end of the super cheap ones. And what’s happened is that the expensive ones use some kind of scanning UV laser. The idea is that you have this resin that’s hardened by light. So you have a vat with a glass bottom and you shine UV light up from below and it hardens a thin layer of resin, and then the build plate moves up just a little bit and new resin flows in underneath. And then you harden again a different pattern. And the expensive ones use either a UV laser or a digital light processor chip with some kind of UV light source, and it’s optically messy and expensive. It seemed out of reach and the resin was too expensive. What people figured out is you can take a commodity off the shelf, cell phone LCD panel, like you’d have on any standard phone, a retina resolution display, you leave out the backlight and you leave out the color overlay that makes red, green, and blue pixels. So you just have something like 6 million black and white pixels and you press that right up against the bottom of the glass of the vat and then just shine UV LEDs up from below through the screen. And the spatial resolution of a retina screen times three of its normal resolution because you’ve got three pixels for every ordinary pixel, you don’t have the color, is tremendously high. The dot pitch of those screens is extremely fine and you can build this whole thing for a couple of hundred dollars or buy it for a couple of hundred, you’re building it for much less. And they work great. So I now have a kit, an internal combustion engine kit, and a new one coming out soon that have stereolithography printed crankshafts in them.

Also mentioned:

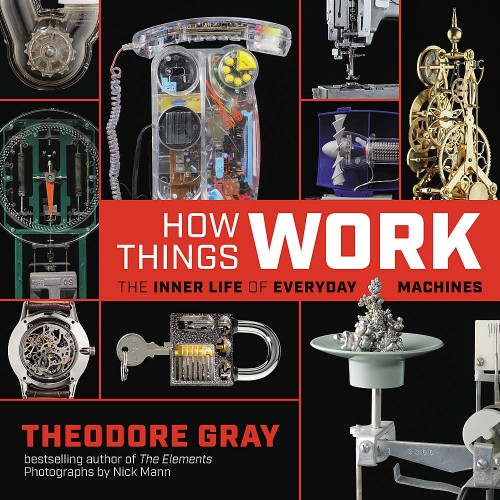

How Things Work: The Inner Life of Everyday Machines

In How Things Work, Theodore explores the mechanical underpinnings of dozens of types of machines and mechanisms, from the cotton gin to the wristwatch to an industrial loom. Filled with stunning original photographs in Gray’s inimitable style, How Things Work is a must-have exploration of stuff—large and small—for any builder, maker or lover of mechanical things.

We have hired professional editors to help create our weekly podcasts and video reviews. So far, Cool Tools listeners have pledged $390 a month. Please consider supporting us on Patreon. We have great rewards for people who contribute! If you would like to make a one-time donation, you can do so using this link: https://paypal.me/cooltools.– MF

01/10/20