“Tips My Dad Says” 2020 Edition

Gareth's Tips, Tools, and Shop Tales - Issue #51

“Tips My Dad Says” 2020 Edition

I got a lot of great submissions of words o’ wisdom from the father figures in your lives. A lot of them were tried and true, like “Measure twice, cut once,” “If it’s worth doing, it’s worth doing right,” “Don’t force it,” “If you can’t fix it the first time, get a bigger hammer!,” “When your only tool is a hammer, everything looks like a nail,” “It’s better to have it and not need it, than need it and not have it,” etc.

Here are some of my favorite submissions:

You can’t learn anything with your mouth open.

(I was asking too many questions at the time he told me this. – Randy Sanderson)

Is it complex or merely complicated?

(My Dad would often ask this when analyzing a mechanical system. -Randy Fischer)

Tight is tight. Too tight is loose.

(My Dad always reminded me of this whenever we worked on a project that required tightening a screw or bolt. – Big Mike)

Use the right tool and the tool will do the work.

(From my dad Bruno who was an automotive mechanic and business owner. – Marina Joyce)

Remove the potential energy.

(Said when storing materials. For instance, unlock vise grips before putting them in the toolbox, remove the igniter assembly from the solid rocket booster, that sort of thing. -Randy Fischer)

Always respect the mountain.

(Said at the top of a challenging ski slope, but a saying that applies to much more than skiing. -George Mokray)

It’s easy to make things difficult. It’s difficult to make things easy. -Marty Lang

Don’t put it down, put it away. -Robert George

Think fast and talk slow. Listen, analyze, evaluate, prepare a fallback strategy, then act. -Brain Collins

If you don’t ask, the answer is already no. – Michael Shiloh

Buy the best tools. You’ll only cry once. -Jim Cook

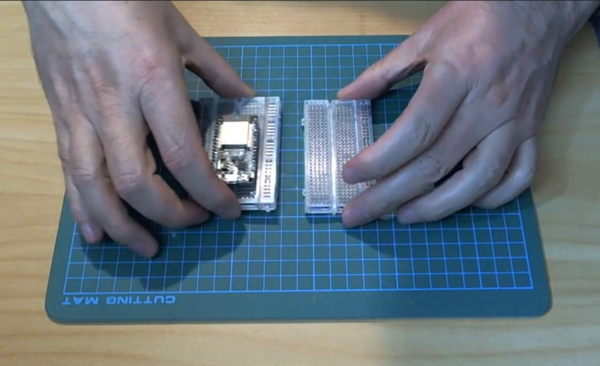

Expanding a Breadboard

Expanding small breadboards is easier than you might think.

Here’s one from my old Make: tips column: This little quick tip on Digicool Things demonstrates how you can easily expand many small breadboards. The type of boards that are clear plastic with a paper backing can be cut (by slicing through the paper) and joined to create the width of board you desire. In the video, he cuts and snaps off a power bus rail on one of two boards and then joins the boards. The remaining power bus on the other board becomes a center trench that ICs can straddle, leaving much more real estate on the expanded board for hooking up components.

Pay No Attention to the Name of that Fancy Paint!

Three shades of olive, never you mind their names!

If you work with craft acrylics or paints formulated for miniature painting (as I do), don’t pay any attention to the colorful product names (Boltgun Metal, Iraqi Sand, Gravedigger Denim). Flip the bottles over and only pay attention to the color seen inside. Some painters even organize their paints by storing them butt-out so that the color values can be seen. If you’re painting something, say in an olive drab, you want to find your undercoat color (a dark olive), basecoat color (a mid-tone olive), and your highlight (a light olive).

Toys!

Andrew playing with his new toy.

I just invested in a portable bandsaw as a result of watching Adam Savage’s “One Day Build” video on Tested and I have to say that it is a magnificent workflow-alteringly piece of equipment. When I think of how much time this tool could have saved me in the past, I feel like an idiot for not biting the bullet and buying it years ago.

I think that in my case, not investing in tools is almost a form of impostor syndrome. For years, I thought that I didn’t deserve expensive tools because I’m not worthy of them. It’s only in the last couple of years that I’ve looked at my accomplishments and thought “actually, I am good enough to use this.” And that’s why I’ve started to approach my workspace and my portfolio with much more confidence.

Recreating Serial Number Plates

Andrew playing with his new toy.

This is one that won’t apply to many of us, but it’s a cool trick that I thought bears sharing. It may have applicability elsewhere. On Hand Tool Rescue, Eric needed to replace the metal serial number plate on a 60s Flymo hover-mower that he was restoring. What he did was to hammer the original serial number onto metal foil tape and then print an image of the original label onto clear adhesive and affix that over the tape. Cut it, apply it, and it’s nearly as good-looking as the original (altho I wonder how waterproof it is).

Shop Talk

My friend Richard Gould, who works in museum exhibition construction, sent me this call for input:

Many of us are beginning to return to work – or soon will be. It’s a little more challenging, I think, in a shop environment. I was told today that we’d have a “clean desk” policy – given that we have our own desks, and how little time we spend at them, I’m unsure what COVID transmission risk is being addressed here. On the other hand, we have a great deal of shared tools and equipment. We have no direction on how we should keep those safe.

I’d be very interested in what ways that your readers are working safely with COVID in shared shop environments.

(Gareth’s Tips, Tools, and Shop Tales is published by Cool Tools Lab. To receive the newsletter a week early, sign up here. — editors)