Tips on Working with Epoxy Clay

Gareth's Tips, Tools, and Shop Tales - Issue #116

Maker Update and Gar’s Tips are doing a giveaway! We’ll be giving away 5 copies of my new book, Tips and Tales from the Workshop, Vol 2 and a grand prize of Volume 1, Vol 2, and the beautiful 3rd edition gift box of The Maker’s Notebook (one of my projects while I was at Make:). All you have to do is go to this Maker Update episode on YouTube and leave a tip, tool, hack, whatever, in the comments. We’ll select the winners from there.

Tips on Working with Epoxy Clay

In this SteadyCraftin video, the always entertaining and informative CrafsMan offers up his favorite tips for working with epoxy clay. There are a few things I was aware of (and agree on), like using silicone sculpting tools and letting the clay firm up a bit before working it. But I had never heard of Safety Solvent (an alternative to using water to reduce the stickiness of epoxy clay) or why air-drying Apoxie is superior to Super Sculpey in many ways (doesn’t need to be baked, it’s easier to build upon, and it can be readily sanded). A miniatures sculptor from Games Workshop once told me that working with two-part epoxy putty was like sculpting with stale bubble gum. So, anything that can make that process easier is more than welcome.

How Safe is a SawStop Really?

Each year, more over 65,000 professional woodworkers and DIYers have an ugly encounter with a tablesaw. To address the dangers of these tools, a company called SawStop created a tablesaw that instantly seizes the blade if it comes into contact with your fingers or similar meaty bits. This saw has been a game-changer in shop safety. But how reliable is its safety mechanism? Responding to common critical questions online about the saw, Jonathan Katz-Moses did some testing and recording using super slo-mo photography (19,000 FPS HD). The results are amazing, even when using a heavy, multi-blade dado stack.

Maker Slang

Jargon, slang, and tech terms from the many worlds of making.

Dross – The solid impurities that float on the surface of low-melting-point metals like tin, lead, zinc, aluminum. Not to be confused with slag which is dross’ liquid sibling.

MIG like TIG – A type of MIG (Metal Inert Gas) welding where you greatly reduce the feed-rate of the wire and weld slowly so that you build up a glob of metal that you can deposit into the “little row of dimes” that’s the hallmark of TIG (Tungsten Inert Gas) welding.

Schmoo – Slang term for any liquid or gelatinous substance oozing out of something that you’re working on. “Release the schmoo!” Popularized by the potty-mouthed YouTube maker, AvE.

Using Plastic Razors on Resin Printer Screens

I’m a huge fan of plastic razor blades. First developed for the boating industry, these blades are great for removing stubborn stickers and labels and other gummy gunk from hard surfaces without marring them. So, I was thrilled to see this application for using them to remove cured resin from a 3D printer projection screen after a spill. I use my blade almost daily. I will now keep one handy by my recently-acquired Photon S printer.

TOYS! The iFixIt Precision Driver Set

Someone on Facebook recently asked about a screwdriver set for electronics and similar precision work. I rushed to recommend the iFixit set but several people had already beat me to it. This kit is so well thought out and designed, solidly built, with 64 bits of every configuration you’re likely to encounter: Slotted, Phillips, Torx, Torx Security, Square, Pentalobe, Hex, five nutdrivers, and more. There is also a flex extension shaft and the lid acts as a small parts sorting tray.

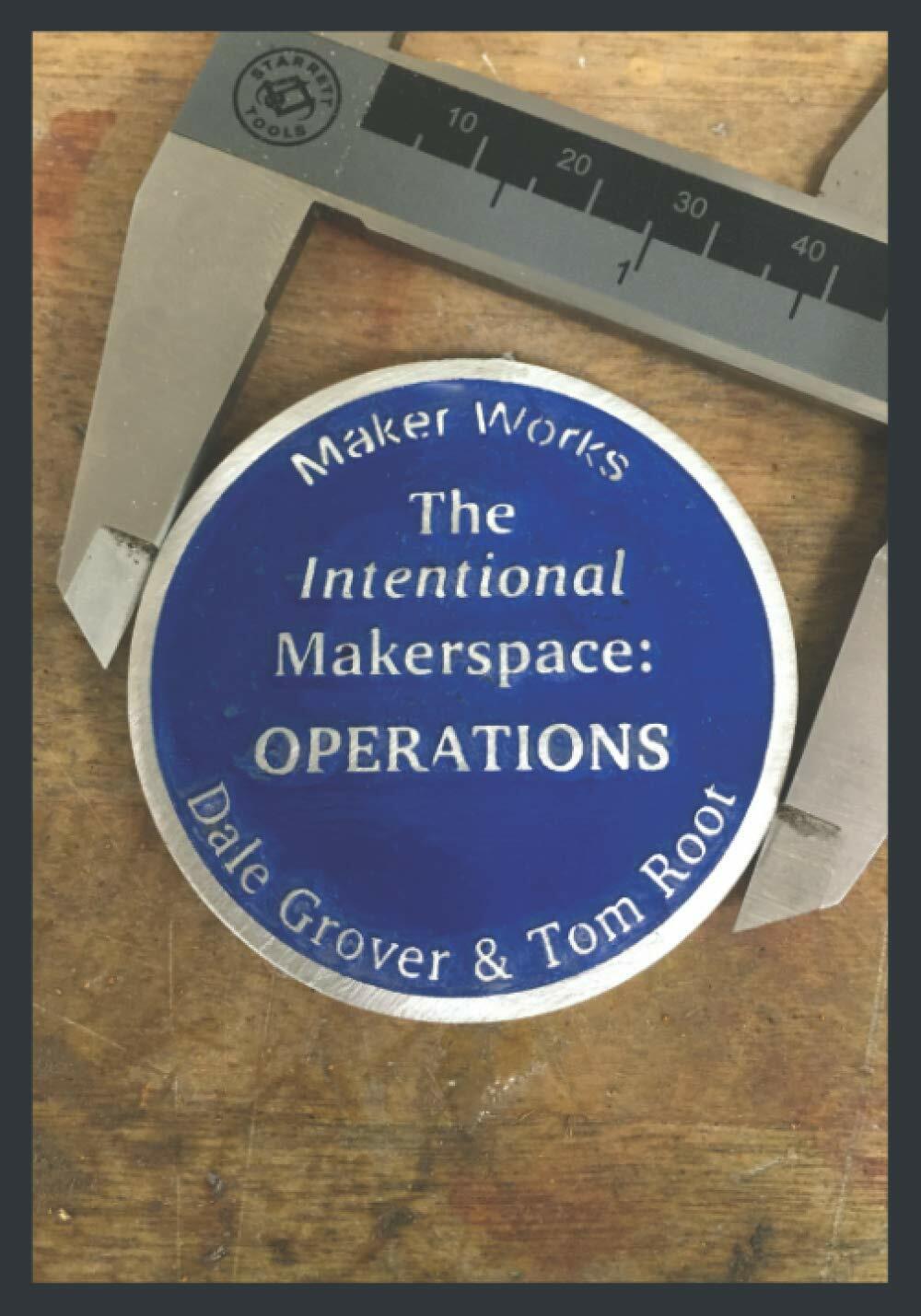

Book Recommendations

Reader Dale Grover was kind enough to send me a copy of his book, The Intentional Makerspace: Operations (co-written with Tom Root). The two run Maker Works, a 14,000 sq. ft. space in Ann Arbor, MI. Anyone who’s been involved in creating and maintaining a makerspace can tell you that there’s a staggering number of moving parts involved. And we’re not talking about the machines! So many challenges in getting, finding, and maintaining a physical space, recruiting and keeping members, teaching members how to use the tools, safety issues, organizing spaces that work well and encourage members to clean up and put their tools back, and on and on. This book thoughfully and methodically covers a lot of this (on both a meta and practical level). Most of the book is designed around the concept of SOPs (Standard Operating Procedures). They describe a SOP as similar to a recipe in cooking. A SOP identifies the issue being addressed, the ingredients required, and the steps to put it all together and achieve the desired goal. The Intentional Makerspace: Operations is largely a cookbook for operating a makerspace. Any makerspace/hackerspace/communal shop, large or small, will find lots of enticing and inspiring recipes in this book.

Shop Talk

When I published the piece “What’s the Deal with Flat Washers?” in the last newsletter, and included an image with a bunch of different washers, I knew I was in for some email. Several people, responding to the image not the article, ranted that lock washers don’t really work, one person pointed out that a water-proofing washer is better known as a gasket, and people sent messages about the many washers that weren’t in the picture. I knew I should’ve just used a picture of common flat washers!

Reader Reid Fisher wrote in to say:

“You might want to add that there are spring washers, which are intended to reduce wobble in a pivot. I realized this when taking apart a pair of hand garden pruning shears. The nut that adjusts the pivot has a spring washer, so the handles can still be moved, but without binding or wobble. They’re the ones that look like a regular thin washer, but are bent. A friend replaced a lost spring washer with a flat one and couldn’t get the handles to pivot right until we realized it needed a spring washer.”

On Cool Tools, KokoTheTalking Ape said (and others emailed with similar):

“Besides the ones listed, washers have another purpose, which is to protect materials from the twisting action of the fastener, which can cause one piece to twist and misalign, or perhaps distort or damage it (say when you’re screwing some canvas to a wood beam). Another purpose is to act as a standoff, to create space between the two pieces being joined.”

Steven Kelby Mclachlan:

“The only lock washers that actually work are made by Nordlock.”

04/14/22