06 March 2026

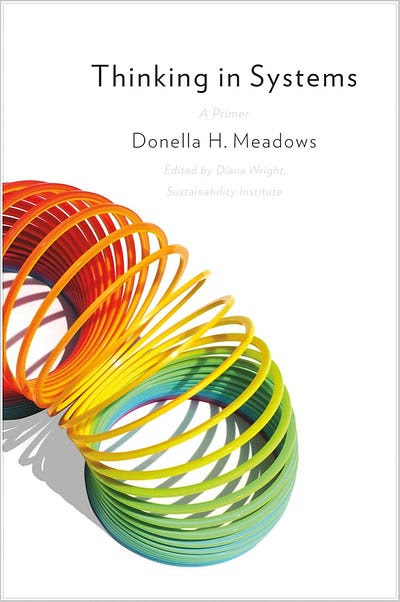

Book Freak #199: Thinking in Systems

A Powerful Framework for Understanding Complexity

From the lead author of the landmark Limits to Growth report, Thinking in Systems offers a powerful framework for understanding complexity — revealing that war, hunger, poverty, and environmental destruction aren’t isolated problems but system failures that can’t be solved by fixing one piece in isolation.

Core Principles

Systems Generate Their Own Behavior

A system is a set of interconnected elements that produces its own pattern of behavior over time. The behavior emerges from the structure — the feedback loops, delays, and connections — not from external events. Stop looking for who’s to blame; instead, ask “What’s the system?” The system itself causes its own behavior.

Stocks and Flows Drive Dynamics

Every system has stocks (accumulations like water in a bathtub, money in an account, or carbon in the atmosphere) and flows (the rates at which stocks change). Understanding which stocks are critical and what controls their flows reveals why systems behave as they do — and why they often resist our attempts to change them.

Feedback Loops Create Stability or Growth

Balancing feedback loops push toward equilibrium (a thermostat maintaining temperature). Reinforcing feedback loops amplify change (compound interest, viral spread, erosion of trust). Most real-world systems contain both types interacting in complex ways. Finding and understanding these loops is key to understanding any system.

Find the Leverage Points

Not all interventions are equal. The highest leverage often lies not in pushing harder but in changing the system’s goals, rules, or underlying paradigms. A small shift in the right place — like changing what gets measured, or who has information — can produce large changes in behavior.

Try It Now

- Pick a problem you’re struggling with. Instead of asking “Who caused this?”, ask “What’s the system that’s producing this outcome?”

- Identify the stocks involved (what’s accumulating or depleting?) and the flows (what’s increasing or decreasing those stocks?).

- Look for feedback loops: Is there a balancing loop keeping things stuck? A reinforcing loop making things worse?

- Ask: Where is information missing? Often system malfunctions stem from key players not having access to the right information.

- Consider: What would happen if you changed the goal or what gets measured, rather than just pushing harder on the current approach?

Quote

“Let’s face it, the universe is messy. It is nonlinear, turbulent, and chaotic. It is dynamic. It spends its time in transient behavior on its way to somewhere else, not in mathematically neat equilibria. It self-organizes and evolves. It creates diversity, not uniformity. That’s what makes the world interesting, that’s what makes it beautiful, and that’s what makes it work.”

Book Freak is published by Cool Tools Lab, a small company of three people. We also run Recomendo, the Cool Tools website, a YouTube channel and podcast, and other newsletters, including Recomendo Deals, Gar’s Tips & Tools, Nomadico, What’s in my NOW?, Tools for Possibilities, Books That Belong On Paper, and Book Freak.

03/6/2605 March 2026

Ski Coat Sales/Delayed Luggage Tactics/Another United Devaluation

Nomadico issue #196

Buy That Ski Coat on Sale

I’m currently leading a group ski trip around Jasna, Slovakia, and one of the participants said, “Here’s a game for when you’re waiting in the lift line. Try to spot two jackets that are the same. It almost never happens.” I looked all day and he was right. That tells me that a) the market is very fragmented and b) the brand doesn’t matter as much as they would like you to believe as long as it’s well-made. I’ve personally used ones from Hi-Tec, Adidas, and Kuhl the past few trips and all have performed great. So buy when the best sales are going on and just make sure it has a left breast pocket or sleeve pocket for today’s digital lift tickets.

Preparing for Delayed Luggage

Delta sent my Prague-bound suitcase full of ski clothing to Pittsburg instead on this trip and it took partner KLM 2.5 days to get it back in my hands, despite the bar code still being attached. That’s a new record for me, with things normally resolved in a day at most. Thankfully I had enough essentials in my laptop bag that it was an annoyance, not a catastrophe, but it’s a reminder that you have to anticipate this scenario and say, “What if?” In most cases the airline will compensate for reasonable purchases, but any good travel insurance policy will kick in if that doesn’t work.

United Will Penalize Fliers Who Don’t Carry Their Credit Card

United just devalued their loyalty program again, which is nothing new, but this time they took it an extra step. They basically said, “Pay up for one of our credit cards or you’re not going to get the same benefits.” In case you were wondering what your airline loyalty is really worth, apparently the answer is “a $150 or more annual subscription fee.” If you don’t have their card, your loyalty status won’t matter: you will get penalized on both the earnings and redemptions. See more info here.

Fake Travel Confirmations

I have seen a slew of articles lately about travelers getting scammed by fake confirmations or change notifications that look just like the official ones from your airline, hotel company, or OTA. In most cases, the aim is to get as much of your personal information as possible. They can be very convincing, but never click on the link and start entering info: go to the official website or app. If your password manager doesn’t fill in your log-in info automatically, that’s the first sign you’re not in the right place. A legit e-mail will tell you to do the same and if you have the app, you’ll get an alert about real flight changes or problems.

A weekly newsletter with four quick bites, edited by Tim Leffel, author of A Better Life for Half the Price and The World’s Cheapest Destinations. See past editions here, where your like-minded friends can subscribe and join you.

03/5/2604 March 2026

What’s in my NOW? — Amanda McClendon

issue #244

I’m a librarian, but I don’t do whatever you think of when you think of what librarians do. I also host trivia on Monday nights at a local Tex-Mex restaurant, work on a master’s degree in theology, and listen to too many podcasts during whatever free time I have left. — Amanda McClendon

PHYSICAL

- Oven pull – These are wood or silicone sticks with two notches. You grab your oven rack with it to get it in and out of the oven while putting some distance between yourself and a very hot metal box, so you’re less likely to burn yourself.

- Keats & Co. Evensong Chai – Caffeine free (it’s rooibos), plus all the profits go to tuberculosis treatment. Good.store, which runs the brand, is a great company run by internet celebrities John and Hank Green and they have all kinds of other good products as well.

- Public libraries! – Listen, I work at an academic library, and I still hit up my local public library all the time, because they have items for checkout that my workplace doesn’t have, and they’re one of the last places in American society where you can hang out and they won’t ask you for money (save for maybe late fees). Plus they may have programs and items you weren’t expecting, like board games, odd kitchen equipment, tax prep help, passport services, free museum passes, or makerspaces.

DIGITAL

- Kung Fu Grandpa in the Food Lion parking lot! – The narration combined with the absurdity of the guy messing with nunchucks in the grocery store parking lot is pure gold.

- Worlds Beyond Number – If you had asked me a year ago if I would be interested in a podcast of four people playing DND together, I would have said no. Past me would have been wrong. Some of the best audio storytelling, and a lot of that is due to the friendship between the four players, all with improv backgrounds. (But also: The editing and sound design are pretty killer as well.)

INVISIBLE

“Do not be daunted by the enormity of the world’s grief. Do justly, now. Love mercy, now. Walk humbly, now. You are not obligated to complete the work, but neither are you free to abandon it” — Pirkei Avot, 2:16

Especially helpful in these times!

Sign up here to get What’s in my NOW? a week early in your inbox.

03/4/2603 March 2026

Smuggler’s Cove / Hieronymous Bosch

Issue No. 107

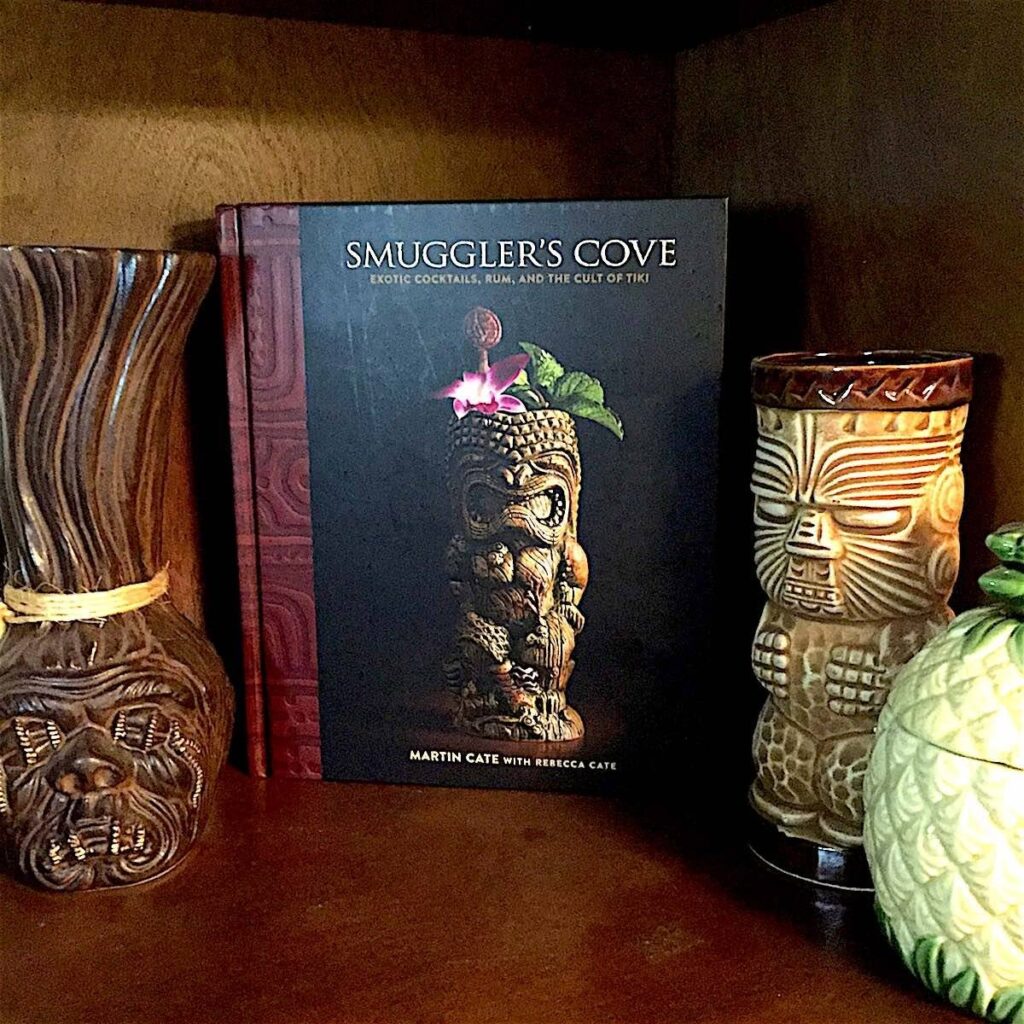

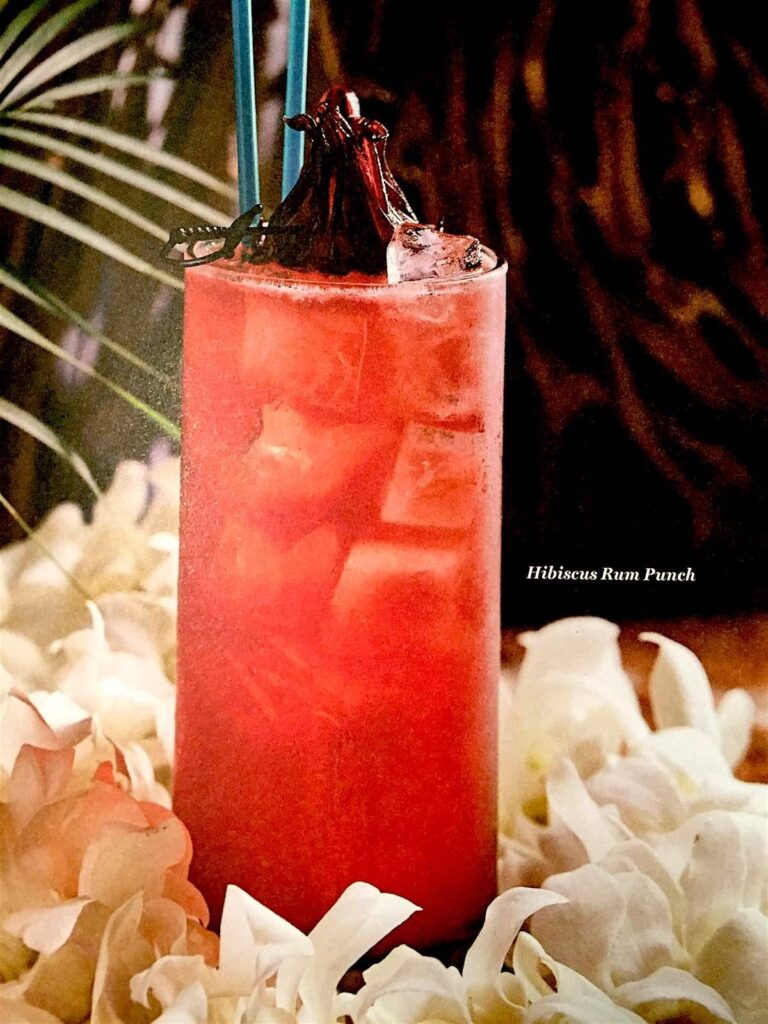

SMUGGLER’S COVE – DRINK YOUR WAY THROUGH TIKI HISTORY WITH EXOTIC RECIPES EVERY STEP OF THE WAY

Smuggler’s Cove: Exotic Cocktails, Rum, and the Cult of Tiki

by Martin Cate and Rebecca Cate

Ten Speed Press

2016, 352 pages, 7.7 x 9.3 x 1.3 inches

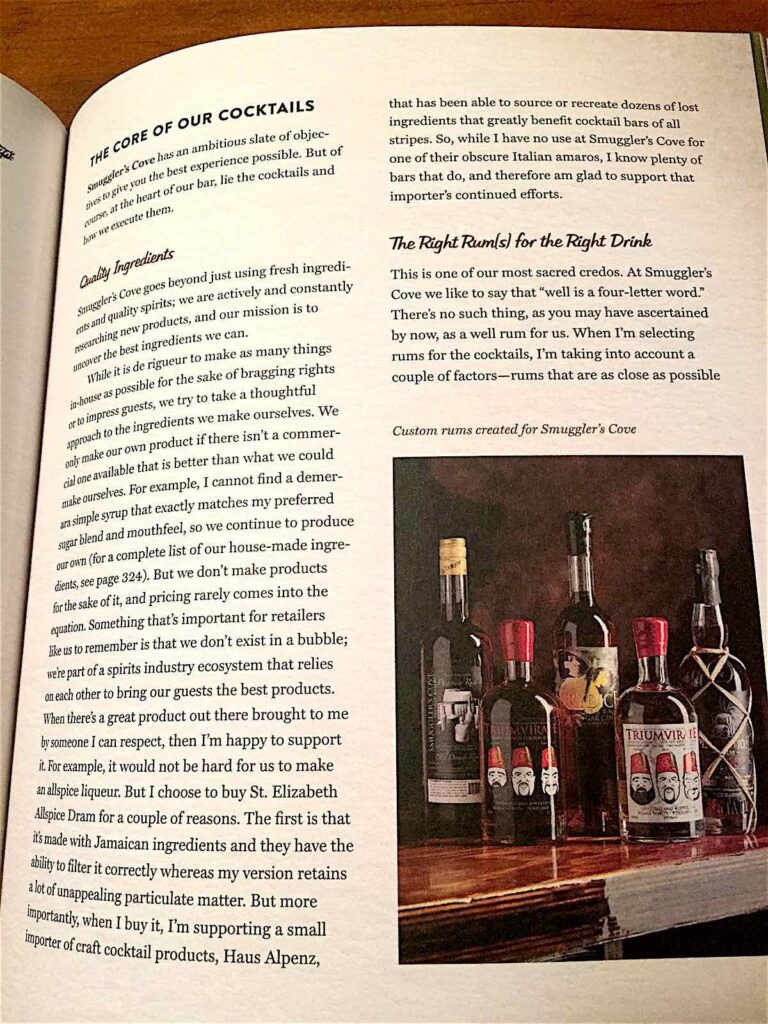

There are good bars, bad ones, and then there are destinations. I’ve been to many tiki bars, but Smuggler’s Cove stands out. In the heart of San Francisco, Smuggler’s Cove is an oasis. From the outside it looks like a weird office building with blacked out windows. Yet when you step inside you are teleported to paradise. It’s small, warm, and since I left the Bay Area, I dream about their drinks. Without question this is one of my favorite places in the world, and this book manages to capture that.

The book has you drinking your way through tiki history, starting with the birth of tiki and moving to the modern tiki revival, with recipes at every step of the way. Topics include the importance of rum, getting the right tiki look and feel, and the creation of the Smuggler’s Cove bar itself. And then there are the drinks.

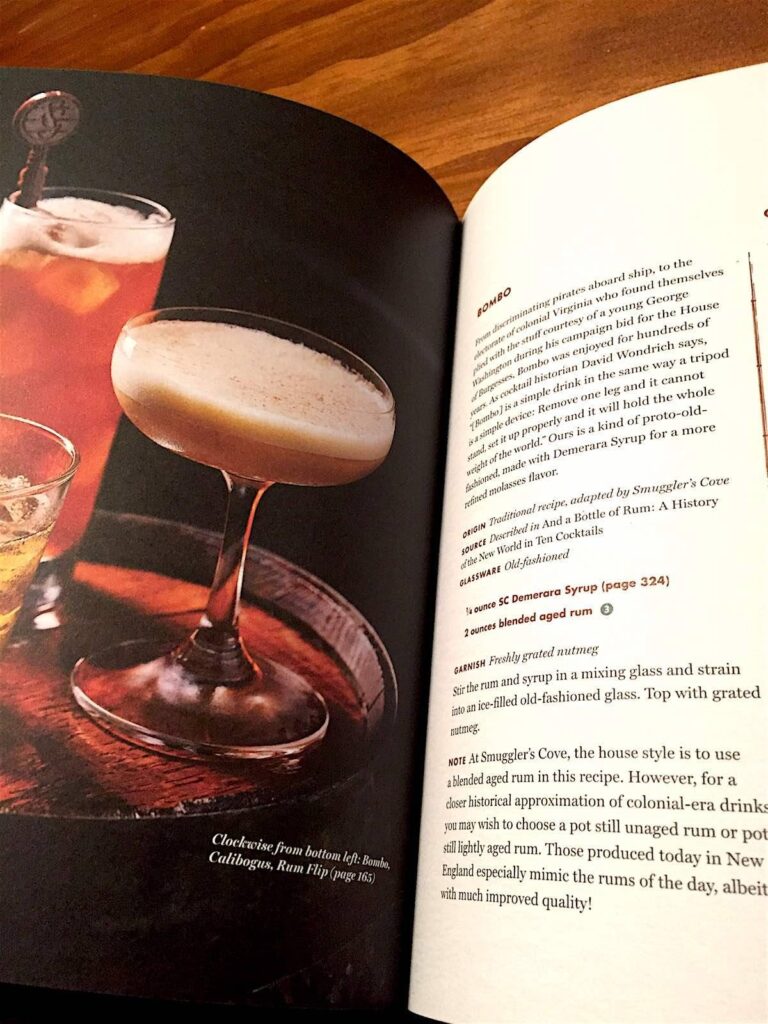

If you like a good cocktail you’re going to find something here that interests you. Grog, Scorpion Bowls, Mai Tais, punch, and Zombies all filled with fresh juice and booze. One thing you’ll learn from reading this book and trying their drinks is that a tiki cocktail doesn’t have to be sickeningly sweet. They’re balanced, delicious, and complex. If you’re into tiki, cocktail culture, or just delicious fancy drinks, you should get this book. No question. Beautiful photography, in-depth recipes, the book’s amazing. But… (pause for effect) they left out my favorite Smuggler’s Cove drink.

On various occasions I’ve worked my way through their menu, trying dozens of their signature cocktails. The one that always stood out was their Painkiller. It’s a coconutty, sour, sweet, spicy concoction that cures all ailments. It was the first recipe I looked for when I picked up my copy, and I couldn’t find it anywhere. I wanted to cry. Buy this book for every other recipe, but until they unveil their secret formula, here’s the closest I’ve been able to get to replicating it.

1oz Smuggler’s Cove Coconut Cream (recipe found in book)

1oz Fresh squeezed orange juice

4oz Pineapple juice

2, 3, or 4 oz of Pusser’s Navy rum (depending on how much pain you’re in)

Top with fresh grated nutmeg

Serve in your favorite tiki mug filled with crushed ice – JP LeRoux

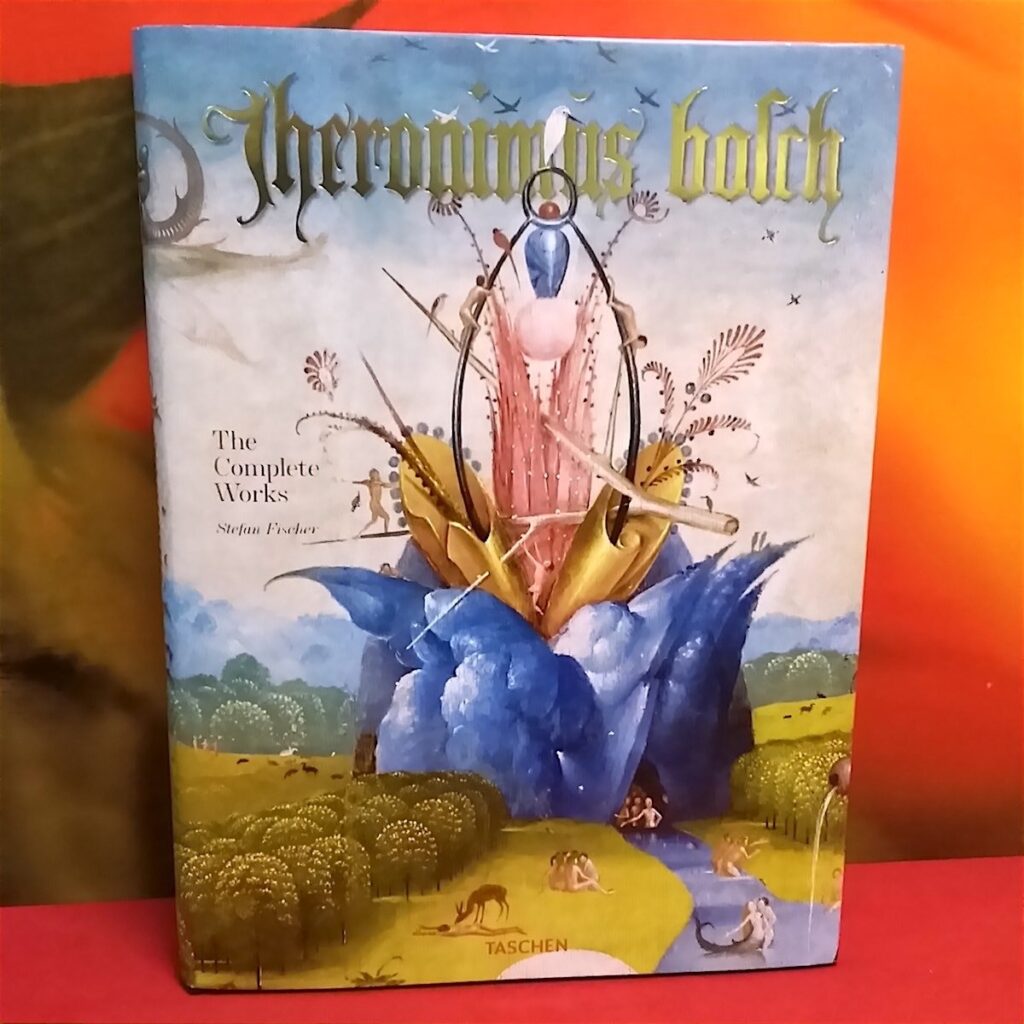

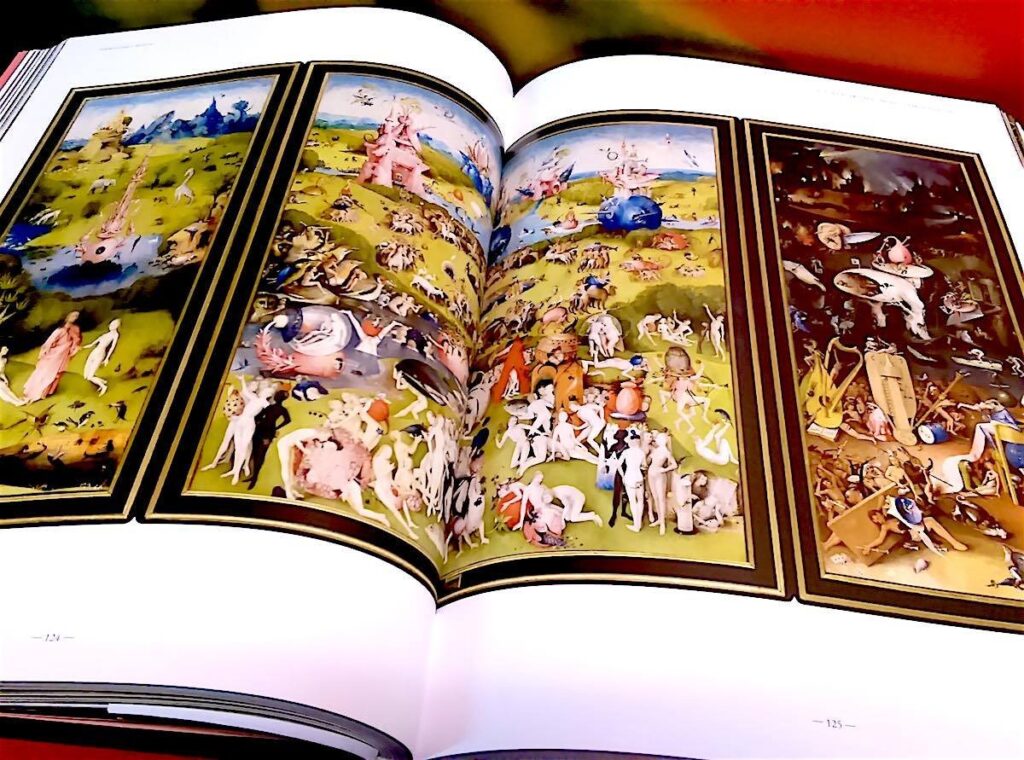

HIERONYMOUS BOSCH: COMPLETE WORKS – A VISUAL MARVEL, AN ENLIGHTENING READ

Hieronymous Bosch: Complete Works

by Stefan Fischer (author) and Hieronymus Bosch (artist)

Taschen

2016, 300 pages, 9.7 x 13.1 x 1.2 inches

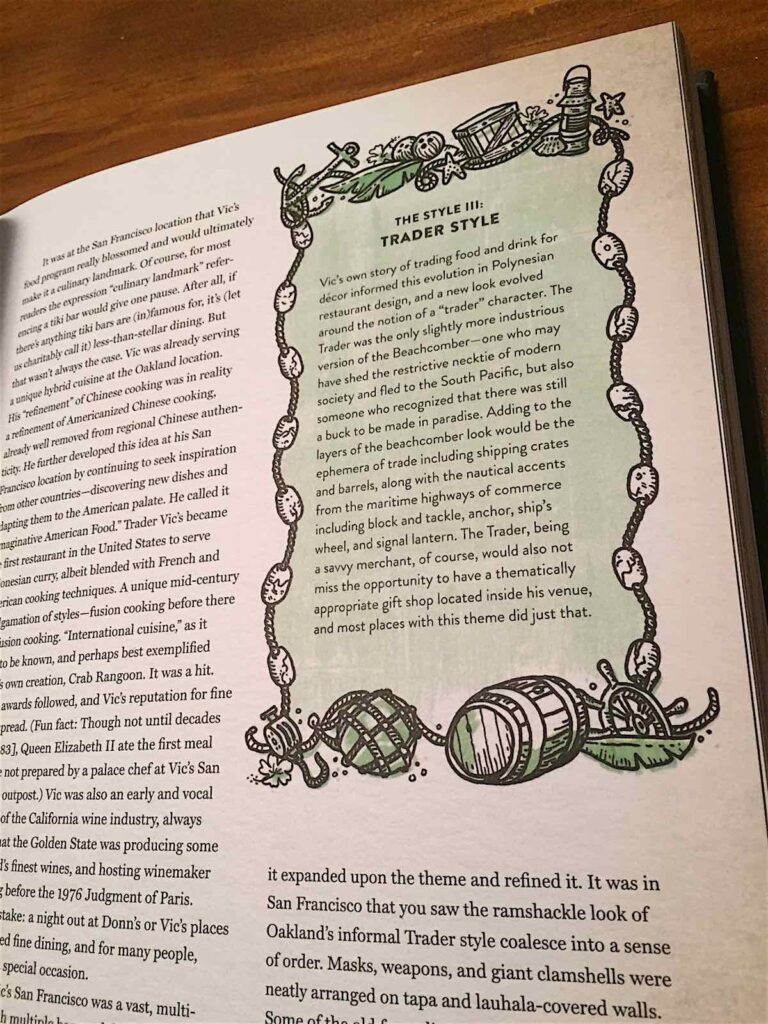

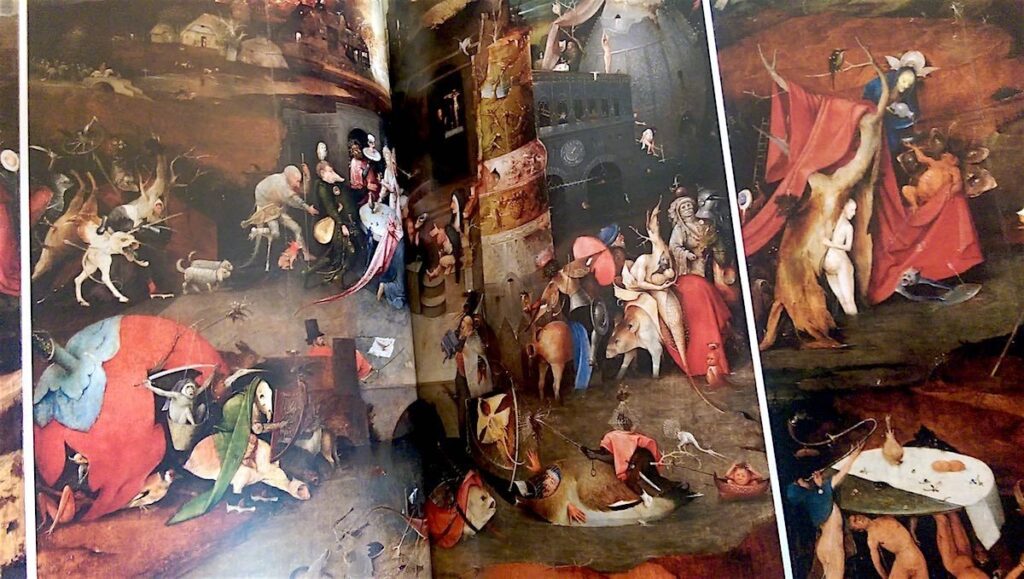

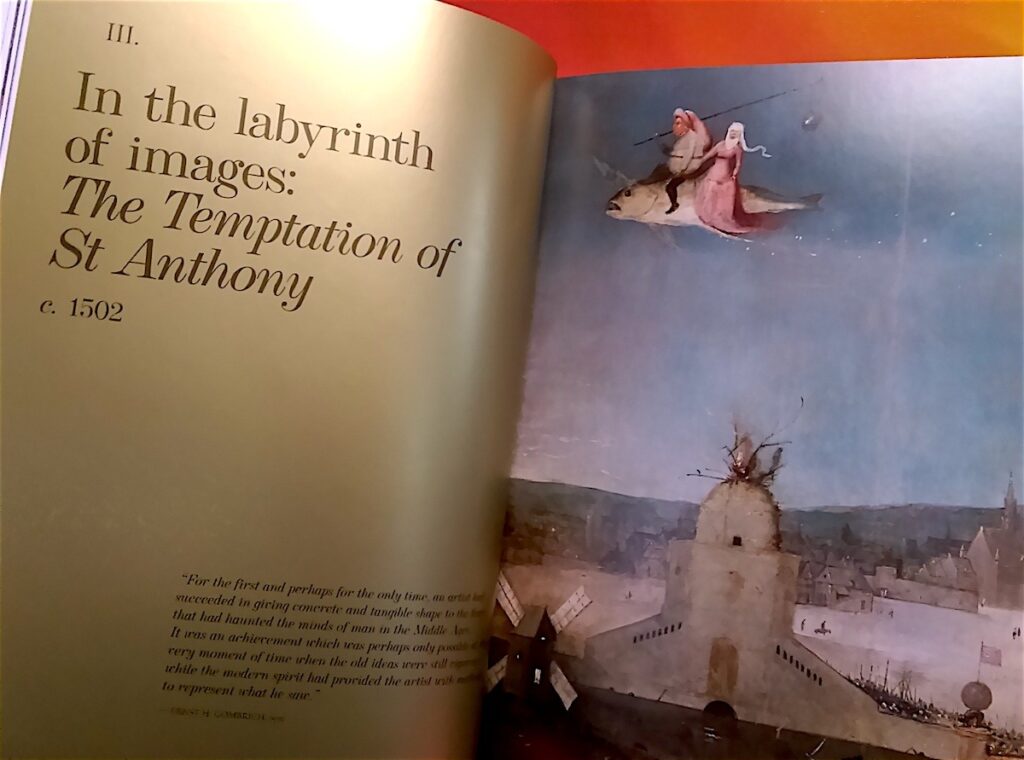

It is, perhaps, fitting that we know the date of Heironymous Bosch’s death while his date of birth remains unclear. We know that Bosch died 500 years ago and so much of what he left us is directly concerned with the afterlife or at least the spiritual journeys that humanity takes to the endpoint of life. The artwork of Bosch is wholly concerned with Christian allegory of the most human, inhuman, and superhuman variety. When one comes to behold a Bosch masterpiece, the lives of saints and the woes of sinners are the subject matter, and sometimes they are one and the same. There is a complexity that is easily identified in any one Bosch piece, but unravelling the intertwined religious and cultural allegories is beyond most. In Heironymous Bosch, The Complete Works, we are offered a unique opportunity, not only to demystify singular works of Bosch, but to take in the entire life and progression of this artist’s journey.

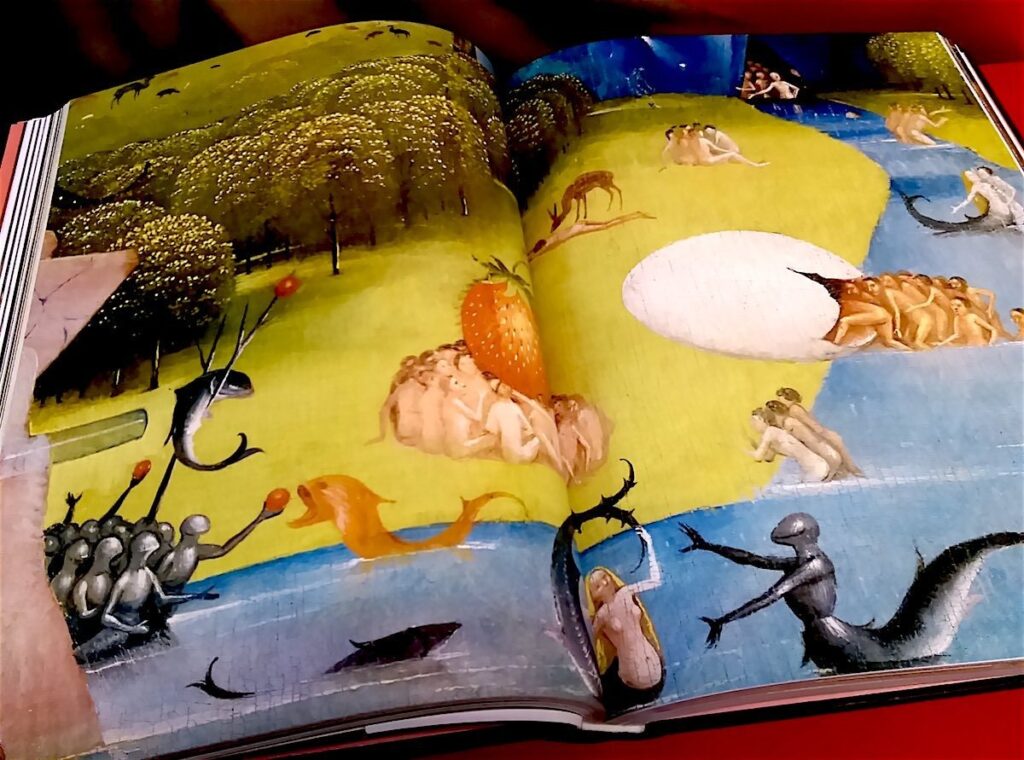

Bosch is a subject of his particular epoch and circumstance, as well as an innovator that transcends both. Granted access to the scholarly resources of the Brotherhood of Our Blessed Lady in the late-medieval and Netherlandish-provincial town of ‘s-Hertogenbosch, the layman Heironymous was given a unique perspective that very few outside the clergy enjoyed in this period. To look upon his works, from The Garden of Earthly Delights to The Last Judgement, one is not just witnessing the depiction of an event from scripture but rather a studied worldview, laid out in full, of a transitional moment between the late Gothic and early Renaissance.

Heironymous Bosch, The Complete Works may be primarily an art book at which one can visually marvel for hours, but it is well worth noting that the textual journey is equal to the imagery on display. It is genuinely surprising that this book is so very enlightening in the text by Stefan Fischer that accompanies the works themselves. While our modern tendency might be to shallowly interpret the many impish grotesques that populate Bosch’s work as overt evil by their displeasing appearance alone, in doing so we would miss the deeper religious allegory, the intertextual allusions to a tradition of religious artwork, and the genius of the original hybrid drolleries that Bosch uses to symbolize, in sometimes quite elaborate visual metaphors, the vices of humankind. Fischer guides the reader through these works, adeptly identifying not just what is being displayed, but why these creatures exist on the canvas. As a result, Fischer’s text becomes profoundly useful for navigating and better appreciating the meticulous detail of Bosch’s overwhelmingly busy scene-scapes.

Take, for example, from The Temptation of St. Anthony the creature on skates with a note pierced by its beak and a funnel for a hat from which extrudes a branch with a red ball tied to it by a string. Whereas I would simply be perplexed by this odd monstrosity, Fischer explains these details fully. The devil messenger bears a letter of indictment for St. Anthony’s sins and he skates to invoke from the local vernacular an adage similar to “skating on thin ice” in relation to the saint’s carelessness in his prior ways. As for the hat, it is the manifestation of these past sins with the funnel representing drunkenness just as the red ball tied to the twig represents carnal desire linked to the withering of the soul. One quickly gains an extraordinary appreciation for the complexity of Bosch’s oeuvre and it is thanks in great part to Fischer’s guidance of the readers through this fraught terrain.

This volume has been thoughtfully compiled as it includes the complete works of Bosch lavishly reproduced in both their entirety and with detailed closeups of particular portions of each work. Moreover, there are inclusions of near-contemporaneous works that inspired or were inspired by Bosch, as well as his sketches and even works created by his workshop followers. The sheer number of visual reproductions in this volume is staggering, and the physical book is a hefty object. While this review concerns the 2016 new edition, due to the timeliness of the 500-year span from Bosch’s death, Taschen has also just released a size-reduced edition with an increased page count. Whichever format one chooses to take in the magnificently bizarre works of Bosch, these releases by Taschen with the meticulous guidance by Fischer are more than collectors’ pieces. Just as Bosch’s works sought to entertain the eye while also teaching the soul, so too do these editions of Heironymous Bosch, The Complete Works seek to reproduce the spectacle of Bosch’s genius and provide the explanatory text necessary to truly appreciate the power of these otherworldly delights. – Stephen Webb

Books That Belong On Paper first appeared on the web as Wink Books and was edited by Carla Sinclair. Sign up here to get the issues a week early in your inbox.

03/3/2602 March 2026

E-Books

Tools for Possibilities: issue no. 179

Public access ebooks

How to Find Free and Cheap Ebooks

Where I live, decent public libraries with connections to the software service Overdrive allow surprisingly easy checkout of “library books” wirelessly to your Kindle. The Overdrive system provides libraries with both audiobook downloads and eBooks. I find, like most, that reading or listening to these books on a computer is untenable, but transferring audiobooks to my Sansa Clip player is as easy as pie.

For the (increasingly) large selection of books with Kindle versions, it’s very easy to get free content to show up via Amazon’s Whispernet. Nothing fiddly about it, no cables either. And for the earlier cool tool of “User Manual First“, Kindles are a pretty good place to keep these PDF files. Either transfer via cable (easy) or use your Kindle’s email address which allow your docs to show up via Whispernet.

Finally, if you sign up for Amazon Prime service, you not only get free shipping on your purchases, you also get access to the “Kindle Owner’s Library” – more books without fees. And if your Kindle is a Fire (or you don’t mind watching on a PC), you also get access to lots of streaming video (my wife is re-enjoying Ally McBeal (and I’m enjoying not being exposed to it, too)).

Anyway, go to your library’s website and look for Overdrive services. Another convergence of several cool tools that merge to form a new level of cool tool. — Wayne Ruffner

Retailers like Amazon and Barnes and Noble have the lock on bestsellers and the like, but a flourishing underground market for free and cheap ebooks has become a boon for readers.

The best established source for free ebooks is Project Gutenberg whose archives contain over 36,000 ebooks that represent nearly every out-of copyright classic piece of literature along with a vast archive of obscure but pleasurable reads. The quality of digitization is excellent, and the site’s vibrant community ensures that any errors are quickly fixed. They also offer the ebooks in a variety of formats (ePub, mobi, html), including some as downloadable audiobooks.

With more and more libraries getting into the game of lending ebooks, the software company Overdrive (that Wayne mentioned) has been leading the way. Libraries contract out their ebook libraries to OverDrive who make them available for a limited loan period (via a proprietary DRM from Adobe) through their software that is available on most operating systems including iOS and Android. Once you have the application, simply add your local or state library system (some are better stocked than others) and Overdrive allows you to browse the ebooks that they have available to check out. Everything’s automated so there are no late fees, and often times you can get best sellers without waiting (or, if they’re “checked out” you can reserve them and when they become available they are automatically downloaded).

ManyBooks.net is the friendliest index of free ebooks of the bunch. It will search Project Gutenberg’s archives, as well as troll through numerous other archives. They also provide recommendations and reviews (which is incredibly useful given the sheer number of available titles).

Outside of strictly free sources, InkMesh is the best search engine I have found for identifying if an author or a book is available in ebook form, whether it is free, where I can download it, and in what format. They have also collated a comprehensive list of free ebooks available for a variety of platforms.

Two more sources for the ebook crazy are the blogs Pixel of Ink and Books on the Knob which highlight attractive deals for the Kindle.

Finally, to manage this inundation of ebooks I heartily recommend the previously reviewed Calibre. If you have other recommended sources for eBooks and the like, feel free to leave a note in the comments and I’ll make sure to update this page. — Oliver Hulland

Digital magazines

Longer than a newspaper item but shorter than a book, a magazine article is the ideal length for my attention span. I’d rather spend an hour with a great magazine article rather than read a book any day. Ditto for hopscotching through shallow blogs and newspaper bits. But there are fewer print publications running long form journalism. Ironically, a new website, called Long Form, points to the best long form articles appearing anywhere in print, and also collects the great magazine articles from the past. Long Form fits perfectly into a small ecosystem whereby you can read these great pieces of writing on a Kindle, iPad, or phone. I’ve found the easy-reading portable screens of these tablet devices fit a 1 to 2-hour window perfectly.

Here is how this system works. The Long Form website lists great magazine articles just published as well as past hits from the archives. You mark the articles you want to read, which are then downloaded to your tablet via Instapaper, another website, which has an iPad app and Kindle connection. You can then read the articles, without ads, at your leisure on your gadget. The whole migration is seamless and unconscious.

I mentioned this was an ecosystem. You can also select pieces to read on your tablet or phone directly at Instapaper, which does not specialize in long forms but also includes short pieces. Instapaper’s sister site, The Feature, like Long Form, makes reader selections of the best magazine articles. On both sites you hit a button “Read Later” to move it to your reading device. In fact you can mark any web page to be “read later” from an Instapaper button on your menu bar and it will move it to your tablet, phone, or even RSS feed. And you can send to Instapaper (and therefore to your reading device) any item from your Twitter stream or social apps like Delicious or Digg, Reddit, etc. to be read later on your Kindle or iPad (or computer screen).

However, I prefer to read long form factuals, and so I keep returning to Long Form to find the gems. I particularly enjoy classic great magazine pieces that I missed over the years. In fact, I realized that I’ve never seen a list of the best magazine articles ever, but see no reason not to make one now. If you have a nomination for one of the top 100 magazine articles of all time, please send it to me (with a link if possible). I’ll share what I accumulate on this page here. — KK

Short digital installments of long books

DailyLit sends you bite-sized chunks of public domain books (including many classics) daily, on weekdays, or three times a week via email or RSS — for free. Each serving takes less than five minutes to read, and if you want, they’ll send you the next installment right away if you click a link. So far, I’ve read “Bartleby, the Scrivner” — 18 segments over the course of 3 weeks or so — and I just signed up for Crime and Punishment – more than 240 segments! Yes, it may take 9 months to read, but I’m certainly more likely to finish it this way. I read them in my email reader (Thunderbird) and don’t print them out. The whole idea is to read short segments for a few minutes in your spare time. I’d imagine it would work well on a PDA or Blackberry if you have one (I don’t); if you have a long cab ride or something you can get the next segment immediately. — Jonathan Fromme

Tech knowledge subscription service

I’ve had a subscription to Safari for over five years now. For a monthly fee (pricing is dependent on the plan you choose), Safari grants you instant access to thousands of tech and business-related digital books. New titles become available surprisingly regularly and quickly (occasionally Safari will get the digital version of a title before Amazon does). In short, the service gives me access to a wealth of knowledge in a much less expensive and more convenient manner than any alternative. —Loren Bast

Once a week we’ll send out a page from Cool Tools: A Catalog of Possibilities. The tools might be outdated or obsolete, and the links to them may or may not work. We present these vintage recommendations as is because the possibilities they inspire are new. Sign up here to get Tools for Possibilities a week early in your inbox.

03/2/2601 March 2026

Free sports TV / Hot and cold face wand / Best pencil

Recomendo - issue #503

Free sports TV

I wanted to watch the Superbowl live and the Olympics but I don’t have cable and I don’t subscribe to Peacock. A friend tipped me off to the solution which is a $15 digital antenna. There are tons of no-name generic models. I used the URIIU Digital HDTV Antenna which is cucumber-sized stick with a long cable that plugs into my big LG screen. I now get all the over-the-air commercial-saturated channels for free, including NBC, which is streaming the sports. — KK

Hot and Cold Face Wand

I bought the Therabody TheraFace Depuffing Wand as a Christmas gift to myself. At first I thought of it as a fancy, possibly overpriced ice roller — battery-powered so that it stays consistently cold—but then I realized the real benefit for me is the heat function with its three temperature levels. I give my face a heat massage when my head hurts or I’m feeling anxious, and it helps relax my facial muscles and myself. I keep it at my work desk to soothe my tired eyes from too much screen time. — CD

My favorite mechanical pencil

I’ve tried dozens of mechanical pencils over the years, and my new favorite is the Staedtler Triplus Micro 0.5mm. The triangular barrel feels natural in your hand and doesn’t roll off the table. The twist-up eraser is full-size, and the retractable tip means they won’t stab everything when loose in a bag. Best of all, the lead stays tight in the barrel while writing or drawing. At about $3 each, they’re an easy upgrade from whatever pencil you’re using now. — MF

26 Useful Concepts for 2026

This list of 26 Useful Concepts for 2026 is offered as lenses or perspective shifts for staying afloat in this new age of “slop.” Each one has a short definition—some expose the invisible forces trying to hijack your attention or distort your perception of reality, while others help you stay aligned with your own truth and meaning. I especially loved Cammarata’s Razor: If you want more agency, ask yourself what you’d do if you had ten times more agency — then do it, and The Shower Test: “We’re socially conditioned to chase what we think everyone else wants. But your true heart’s desire can often be found in the thoughts you gravitate to while undistracted, such as in the shower. As Walt Whitman said, ‘If you want to know where your heart is, look to where your mind goes when it wanders.’” I wish I could remember where I first came across this to give credit, but it’s absolutely worth passing around. — CD

Prompt therapy

People can be helped meaningfully by reading books that know nothing about them. If you tell a reputable AI chatbot a lot about yourself, it can help you far more than a book or lecture can. In a 20-minute video Dan Pink crafted a dozen prompts that will enable an AI to give you helpful feedback of a type you may not get from your family and friends. It is a partner in honesty. This kind of prompt therapy is just a first step towards a whole new avenue of self-help that will only expand quickly from now on. I’ve done some of Dan’s prompts and they really will stir up something important in you and for you. — KK

Searchable Cool Tools and Recomendo

We built a companion page for Recomendo that tracks live Amazon prices on every product we’ve ever recommended since 2020 — over 2,500 items from both Recomendo and Cool Tools. Prices update nightly. Sort by biggest discount to find the best deals, filter by price range, or search for a specific product. Each listing links back to the original review. It’s like a permanent, always-updating clearance rack for our recommendations. Bookmark it and check back next time you are ready to buy. — MF

Sign up here to get Recomendo a week early in your inbox.

03/1/26ALL REVIEWS

02/27/26

02/27/26

Book Freak #198: How We Know What Isn’t So

The Fallibility of Human Reason in Everyday Life

02/26/26

02/26/26

Best Hotel Values/Reserved Seat Tactics/Fastest-growing Tourism Destinations

Nomadico issue #195

EDITOR'S FAVORITES

COOL TOOLS SHOW PODCAST

WHAT'S IN MY BAG?

04 March 2026

ABOUT COOL TOOLS

Cool Tools is a web site which recommends the best/cheapest tools available. Tools are defined broadly as anything that can be useful. This includes hand tools, machines, books, software, gadgets, websites, maps, and even ideas. All reviews are positive raves written by real users. We don’t bother with negative reviews because our intent is to only offer the best.

One new tool is posted each weekday. Cool Tools does NOT sell anything. The site provides prices and convenient sources for readers to purchase items.

When Amazon.com is listed as a source (which it often is because of its prices and convenience) Cool Tools receives a fractional fee from Amazon if items are purchased at Amazon on that visit. Cool Tools also earns revenue from Google ads, although we have no foreknowledge nor much control of which ads will appear.

We recently posted a short history of Cool Tools which included current stats as of April 2008. This explains both the genesis of this site, and the tools we use to operate it.