Dan Slaski, Product Designer

Cool Tools Show 202: Dan Slaski

Our guest this week is Dan Slaski. Dan is a product designer, Ironman triathlete and blogger of all things digital manufacturing. By day, he tackles crazy engineering problems and puts machines in some of the world’s harshest environments. By night, he plots to share STEM awesomes through nefarious activities like 3D printing ninja stars and 3D scanning PEZ dispensers.

Subscribe to the Cool Tools Show on iTunes | RSS | Transcript | See all the Cool Tools Show posts on a single page

Show notes:

SolidWorks

I am a professional product designer and it’s an amazing job. It’s taking “Making” and making it a professional job. So, I wanted to share that with people and maybe help people figure out the path to get there if that’s something that sounds cool. SolidWorks is a professional 3D modeling software. The functionality is next level from your homemaker stuff. It has a bunch of analysis tools, so you can do stress analysis and flow analysis and all that kind of stuff. And it really integrates with the company’s manufacturing cycle. You can do drawings, you could do sheet metal, you can create building materials, exploded views. It’s this whole integrated system that basically allows me to be a one person leverager to do the work of multiple people. It’s feature-based, and what that means is, I can change parameters on the fly and the model that I’m working on will scale in real time, particularly if I’ve designed it in a smart way. And that makes it really cool because someone could come in and say “Well, what would this look like if this was a little bit taller or this was a little bit longer,” and it will kind of stretch, and skew and all these things will happen, and your design intent should translate so the holes will move and all this kind of stuff will move as you would intend the design to do. One thing that I want to talk about is that it’s not cheap. There’s certainly other ones that have come along that are much cheaper. But what’s interesting about SolidWorks is historically they’ve owned a large market share of the design space. So I wanted to make people aware of it because if you do want to become a designer, it’s kind of important to get your foot in the door. I think Fusion 360 has taken a lot of the marketplace and there’s one called Onshape that’s also becoming more prevalent.

Making It: Manufacturing Techniques for Product Design

and Google “CNC milling basics” or “CNC milling cost saving tricks

So the next one is this book called Making It: Manufacturing Techniques For Product Design. And the high level tool that I actually wanted to share was understanding manufacturing processes a little bit, because as a designer, myself included, we come out of college with a lot of technical knowledge but very little practical knowledge. So kind of tying it into SolidWorks, you can make a part in SolidWorks that looks great, but it’s totally not manufacturable. There’s a lot of rules of thumb and a lot of different easy to learn things that are obvious once you realize them, that really make you able to design great parts that are affordable and that are manufacturable and that are scalable. This book is actually just like a super primer. It’s just kind of like one-page description of what it is. And then my actual recommendation would be to just Google. A lot of the parts that I do are CNC milled, for example. So if you just were to Google CNC milling tips and tricks you’ll find people that have created web pages with kind of like “Hey, here’s 10 rules: don’t make a pocket with sharp corners and don’t don’t do things like this…” So the first level is just to understand what processes are even out there. And then whichever ones you decide to use, kind of go one level deeper than that. Another book called Machine Shop Trade Secrets would be great one if what you wanted to do is just understand CNC milling, that’d be one I would highly recommend for that. But another pro tip is that there’s all these different sites out there now where you can upload a CAD model, you can even do it directly from SolidWorks, and then it will tell you we can’t machine this part because the corners are too tight or because the pockets are too, and stuff like that. So you can kind of iteratively learn that way. Whereas if you just go to a traditional machine shop, they’ll just come back with a high price or they’ll just tell you no quote and you won’t know what you did wrong that that made it difficult for them to machine

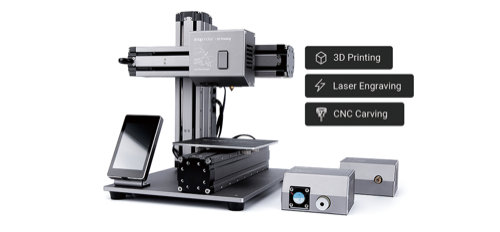

Snapmaker

I’m a avid fan of 3D printing. I’ve been using the technology for 16 years since I went to college. I went to Virginia tech and they had one of the first additive manufacturing courses in the country. And at the time it was pretty much a novelty. And now I can’t believe how far it’s come as far as accessibility and ease of use. And I get the question all the time, what 3D printer would you recommend? And the answer is it depends, right? It’s kind of like what bike would you recommend? Because there’s different ones for different purposes. Do you want a mountain bike? You want a road bike? What’s your budget? There’s all these different things. There’s kind of no, one right one, and there’s no perfect one. I really like the Snapmaker a lot. I did a review of this one. First of all it’s cool because it’s a 3-in-1. So it’s an FDM printer — Fused Deposition Modeling. That’s the kind of 3D printing they call the hot glue kind, where it extrudes the filament out of a hot end and does it layer by layer. It’s also a laser engraver and a CNC Carver. I made a cool Ninja star as kind of a fun way to test all three processes. What’s beautiful about this machine is that it does have all three. And I think that’s kind of cool because I’m not sure people are as aware of CNC carving or engraving. 3D printing gets all the hype. I really like this because I think it’s a great primer. I think this should be in every university and Makerspace. It’s robust and it can just kind of bring awareness to all three.

The 180 formula

Switching gears a little bit. I hang out at Makerspaces a lot and I am a triathlete and I see a lot of people at Makerspaces that maybe aren’t eating the best and are a little bit sedentary. So I wanted to do a health and wellness related tool. The 180 formula is pretty simple. Basically you take 180 and you subtract your age and then you can add a little bit or a little less depending on your fitness. But basically that’s the heart rate that you should train at. Basically try and staying at that or below that. And over weeks or months, you’ll see that at that same heart rate, you’re going faster, you’re going longer, all these adaptations start to occur. And the other thing that’s great about it is I see people running and they go off for 20 or 30 minutes and they just look like they’re going full tilt. Right? And they look like they’re in such horrendous pain and that they’re hating every minute of it. And so I think if you do this, it’s actually pleasant. Another way to think about it is called a conversational pace. So you’re going out at a pace where you can actually have a conversation with the person next to you. And so it’s just amazing what happens over time, and you’re burning fat as well, which is I think a goal of a lot of people, but you start to enjoy it and you start to explore your landscape and you just start to see exercising in a completely different way.

We have hired professional editors to help create our weekly podcasts and video reviews. So far, Cool Tools listeners have pledged $390 a month. Please consider supporting us on Patreon. We have great rewards for people who contribute! If you would like to make a one-time donation, you can do so using this link: https://paypal.me/cooltools.– MF

11/29/19