Sanders

Tools for Possibilities: issue no. 39

Once a week we’ll send out a page from Cool Tools: A Catalog of Possibilities. The tools might be outdated or obsolete, but the possibilities they inspire are new. Sign up here to get Tools for Possibilities a week early in your inbox.

Sandpaper for stone

This is sandpaper for stone, ceramic, glass and concrete. The business side of each 4”-diameter pad consists of a polymer honeycomb that looks sort of like the bottom of a sneaker. This “softness” allows it to contour itself to curved surfaces. The elastomer has industrial diamond grit embedded inside. The disc is attached to an electric grinder with an included rubber pad holder covered with black “hook” Velcro on one side and a 5/8- 11 threaded brass insert. That’s a standard grinder arbor thread. The back of each pad is covered with “loop” Velcro and marked with silver numbers indicating the pad’s grit size. The Velcro is also color-coded in case the numerals wear off, which hasn’t happened to mine yet. In use, the matrix slowly wears away exposing fresh diamond grit. I used these for jobs that no sandpaper can handle, like polishing a concrete bowl to expose underlying glass aggregate. I could not have done it without these pads. — Sean Ragan

Small, multi-functional sanding station

Ridgid Oscillating Belt & Spindle Sander

The word that best describes the Ridgid oscillating belt sander is “workhorse.” It is one of those rare tools which ends up at the heart of your workshop — fast, precise, durable. The belt rotates like a standard sander, but also simultaneously and automatically oscillates up and down 60 times per minute, giving you better space coverage and a wider stroke (about 1 in.); this is especially helpful with larger pieces, because you don’t need to reposition or flip the piece to sand the whole thing.

I use mine almost daily to fabricate parts in wood, metal, and plastic. The metal platen provides plenty of support for serious, precision sanding. I routinely sand to the center of a 1/64 slot on an Incra ruler. Not bad. It’s also very quick to swap out the belt and use it as an oscillating spindle sander, meaning you can handle both flat and curved sanding.

It’s designed to sit on a bench top, but they also molded slots into the bottom so that it rests stably on a sawhorse. It has an incredibly well made tilt table, with fence, that folds down onto a molded storage bay which holds all the accessories it comes with. And a vacuum port is molded into the back of the unit for clean up.

Two things to know: I find I often have to adjust the belt tension to prevent the belt from rising or falling, but this is easy to do on account of a large, well-placed knob. Also, the belts and spindles it comes with are extremely aggressive and are meant for hogging away wood. If you want to do more delicate work, you need to get higher mesh belts from a specialty store like Rio Grande, Klingspor, or maybe Grainger or McMaster-Carr. — Sam Mapadatha

Polishing kit

I originally bought the 3M Headlight Polishing Kit in order to remove the haze on my truck’s plastic headlights, but I have since found that it has a plethora of uses. Basically, you use the progressively finer grit sanding surfaces to smooth the plastic and grind away the scratches and finally polish using the 3M rubbing compound. My headlights looked new and were way more effective after the treatment.

The other day I discovered that the compass for my sailboat was scuffed pretty badly, and I tried using the polishing kit to buff it out (after testing on some safety glasses first). The results blew me away. The compass lens was crystal clear! I’ve since been polishing anything plastic that I have that’s been scratched. Calculators, display screens, etc. You could put this kit together yourself with p500, p800, p3000 grit pads and a foam compounding pad with some 3m rubbing compound but the kit is very convenient and should last a long time as long as you use water with the sanding pads. — Jason Tan

Evolved electric sander

It’s been several decades since I bought a wood sander, but I recently needed a new one for a large finishing job. I was pleasantly surprised by the technological advances now standardly available in inexpensive sanders.

There are three key innovations here: “random” sanding patterns, using sandpaper disks that attach via a velcro-like surface, and a vacuum that works through holes in the paper. Together these three features produce a much superior machine to the simple vibrating sander I had before. Random-orbital sanders spin as circles within circles, leaving little discernible pattern of abrasion on the work. The round hook-and-loop paper is magic. These disks securely attachment and detach in a second, and don’t slip. This quickness encourages you to instantly change to the appropriate grit size without hesitation. Lastly, sanding produces massive amounts of dust, and the mini vacuums really decrease the volume of stuff flying around. The debris is sucked into a small cloth bag that doesn’t interfere much with work.

All these features and more are available in higher end machines, but also in cheaper ones as well. I’ve been using a Dewalt, D26451K which is an entry model at about $55 street price. With a coarse grit paper, its 3-amp motor will eat wood if you need to, but it is light enough to feather touch a fine grit. It takes the standard 8-hole hook-and-loop disk. Many companies make these disks in all possible grades, varieties and types. Although they seem expensive, I found these disks lasted longer than the pieces I used to cut from standard sheets for my old machine. The small dust bag is sufficient for most weekend projects, but may seem small if you are sanding whole walls; you just have to empty it more often.

None of these features may be new to most woodworkers, but I have not been paying attention; I wish I had got one of these years ago. — KK

Super fine sandpaper

Micro-Surface makes the finest sandpaper around: Micro-Mesh abrasives. I originally used their sanding pads to get a perfect finish on a plastic model car by sanding each layer of spray paint I applied to the model. Their finest sandpaper is rated at an incredible 12000 grit. (Although that number isn’t using the same ANSI scale as commonly available sandpaper).

I was amazed that I was able to sand a scratched plastic window to perfect clarity, although I shouldn’t have been surprised: micro-mesh is used to repair the acrylic windows used on many airplanes. I’ve since used the same hobby kit for repairing scratches in the clear coat of my REAL car. I’ve even carefully polished out deep scratches in the bottom of several CDs. You can also polish out scratches on reading glasses.

Micro-Surface makes a wide variety of abrasives, in every size and type I can imagine needing. — Mike Gebis

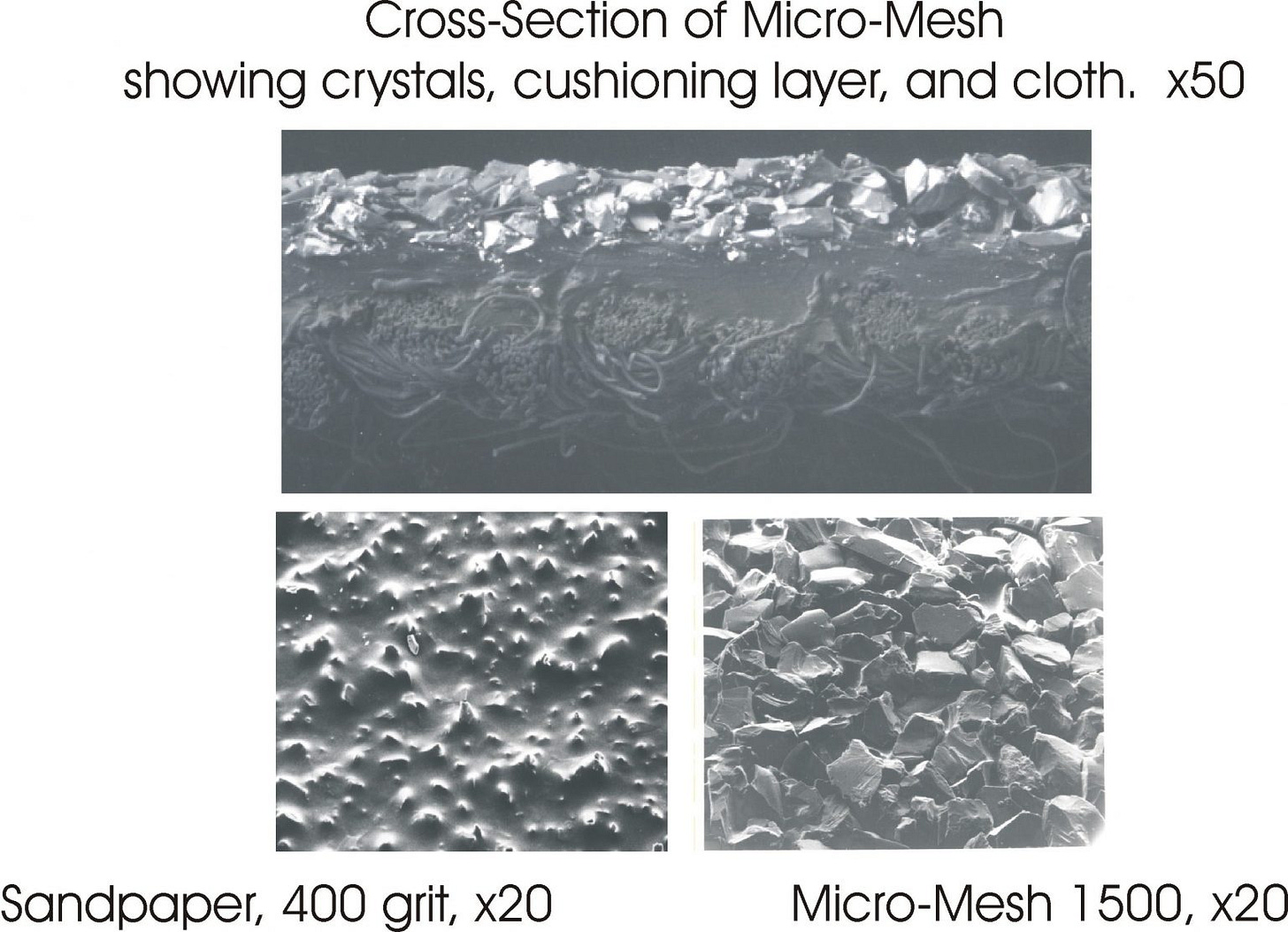

Micro-Mesh is what we like to call a non-abrasive abrasive. It is considered a cushioned abrasive in fact. Conventional sandpaper is designed to be aggressive so that it will dig deeply. In its manufacture the crystals are electrically charged so that they will stand up. They are locked into a hard resin and when you apply the paper to a surface it will literally tear in and remove the substrate of the material you are sanding. The crystals cut in a negative raking motion, leaving inconsistent scratch patterns.

Micro-Mesh does the opposite. The backing is long lasting cloth to which an ultra-flexible cushioning layer is applied. This cushioning layer will determine how far forward you can push crystals before they will penetrate the cushioning layer. On top of this layer, we have a very resilient glue, not a hard resin, but a completely flexible glue that will hold the crystals while allowing it to move and rotate. The crystals can turn in any direction without coming loose. When you start to apply pressure to sand with Micro-Mesh, the crystals will go into the cushioning layer while beginning to cut a bit. If you push harder, they will go further into the cushioning layer, which serves as a safety valve. It determines how much pressure you can exert in a downward direction. Instead of a deep scratch that sandpaper makes, Micro-Mesh produces a refined scratch that is close to a RMS of 1.0. The cushioning layer also allows the crystals to cut with a planing motion that leaves an extremely consistent scratch pattern and allows you to achieve extraordinary levels of gloss.

06/19/23